Keeping Cool in Extreme Heat

A new foam knows how to keep its cool even under extreme high temperatures. NASA's Langley Research Center needed a lightweight foam that could retain its structural integrity under temperatures ranging from -423 to +482 °F, for its second-generation Reusable Launch Vehicles (RLV). Langley's RLV airframe design required new insulation material for the fuel tanks, which are exposed to extreme temperature changes over a matter of seconds.

Through a partnership with Unitika Ltd., NASA's Langley Research Center created a foam based on high temperature resistant polyimide chemistry. The patented foam, named TEEK, is non-exclusively licensed to SORDAL, Inc., of Holland, Michigan.

The new low-density foam can be processed into forms or used to fill structures such as honeycomb. Also unique is its ability to foam in place during installation and repair operations. Most foam must be cut to fit a certain area, and then inserted and molded. This process takes time, and usually a great deal of the product is wasted in the attempt to fit the foam. The new foam is directly applied to the installation or repair site, eliminating the excess foam that is typically cut away and discarded. TEEK offers superior insulation and support qualities, but its greatest advantage is its heat and flame resistance abilities. The TEEK polyimide foam met all of NASA's needs and also managed to drastically reduce the weight of the RLV.

SORDAL recognized the various advantages of the foam and its potential applications, and decided that the new foam would be a wonderful addition to SORDAL's use of composite structures. Within six months of receiving licensing, SORDAL created a successful marketplace for the polyimide foam. Many of the materials already produced by the company are compatible with the foam. The addition of the NASA polyimide foam technology is a natural compliment to our product line, states Dale Danver, CEO of SORDAL.

Thus far, SORDAL has focused commercialization of the foam in the shipbuilding industry. It has proven to be a practical selection for hull insulation, but it has numerous potential applications in other fields. It is projected that the foam will also be used in aerospace applications, fire-resistant construction materials, and a wide range of consumer products that will improve safety and energy efficiency. Other opportunities are available in the areas of automotive coatings and sealants, electrical components, and recreational equipment. Defense and aerospace contractors have utilized the foam because of its unique physical and chemical properties.

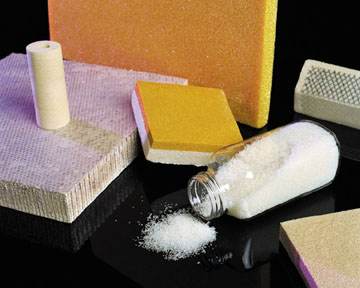

SORDAL has introduced its new product in several different forms, under the name SOLREX. Besides the basic foam, SOLREX can also be purchased in either commercial or maritime grades. It can be preprocessed into neat and syntactic foam, or as foam-filled honeycombs or shapes. Microspheres are also offered. Presently, SORDAL is developing a new product called SORDAL Paper.™ The new product will be used in conjunction with the polyimide foam to offer thermal protection in various products. SORDAL anticipates the use of the companion products in the areas of wireless communications, fire resistant garments, prosthetics, and in many others.

SORDAL Paper™ is a trademark of SORDAL, Inc.

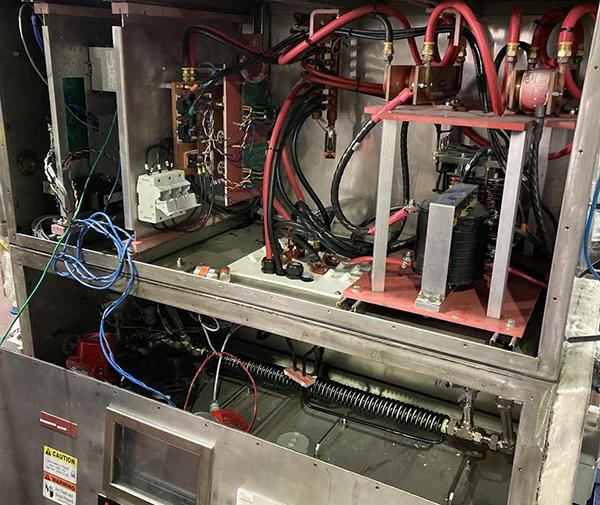

SORDAL, Inc. offers NASA's TEEK polyimide foam in several forms, including microspheres, preprocessed neat and syntactic foam, and foam-filled honeycomb.