NASA Ingredients for Industrial Expedience

Subheadline

NASA funding enables large-scale inductive heating for food production

On a mission to the depths of space, astronauts need to pack more than a lunch.

While trips to the Moon only needed a few days’ worth of meals, a mission to Mars would require years of food supplies that need to be perfectly preserved and ready to eat whenever it’s mealtime for astronauts.

“A closed system can be a challenge, because astronauts have limited resources, and they want some variety in the food they can eat,” said Grace Douglas, lead scientist at the Space Food Systems Laboratory at NASA’s Johnson Space Center in Houston. “But overall, they have to be able to get the nutrition they need to perform.”

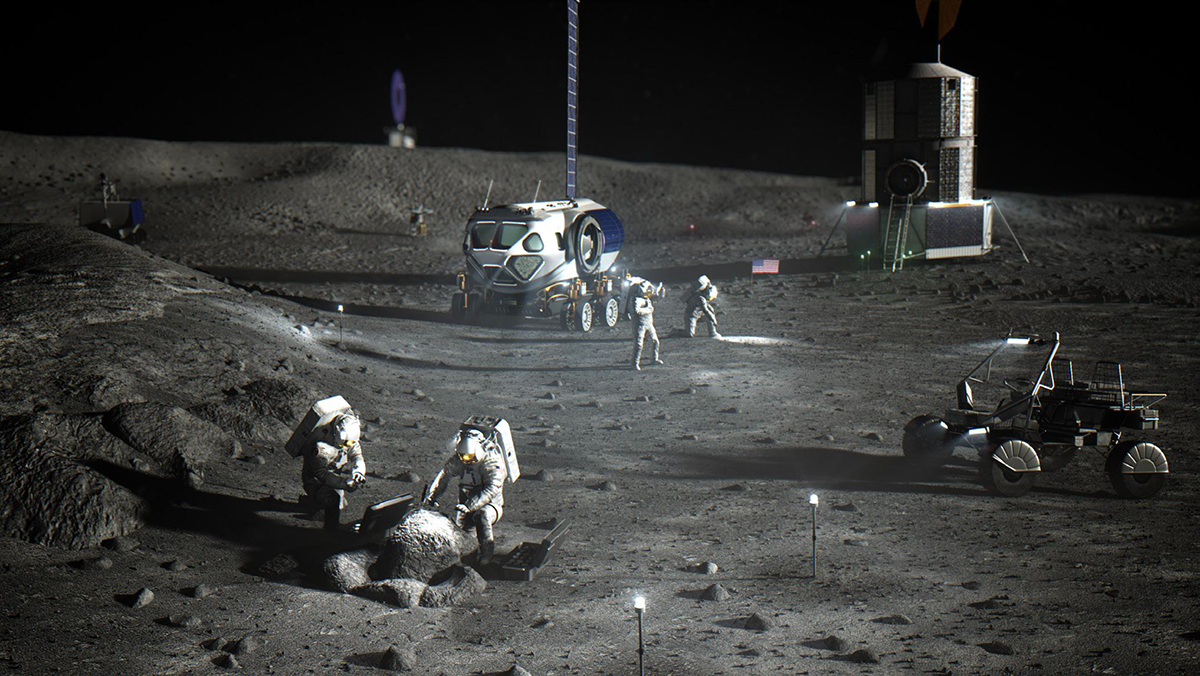

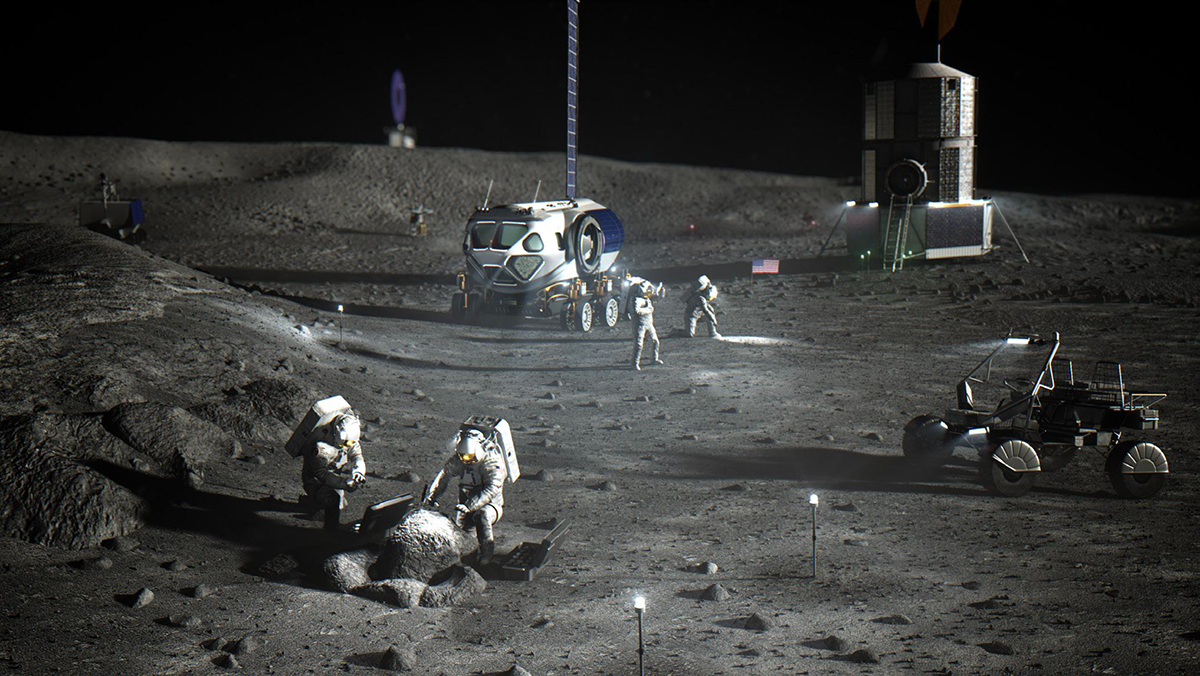

In 2008, NASA’s Small Business Innovation Research (SBIR) program supported the Advanced Food Technology project to explore technologies that could keep astronauts fed on a long-duration space mission. Among the proposals this project explored for a Moon habitat was a stocked kitchen. Instead of ready-to-eat meals, astronauts could select from a variety of preserved ingredients and assemble their own dishes. This would require kitchen appliances that work in low gravity.

Induction Food Systems Inc. (IFS) of Durham, North Carolina, was one company selected for the project after proposing a food preparation system that, in keeping with its name, relied on the process of induction. Anyone who’s walked through an appliance store in the last decade has probably seen an induction cooktop. These use magnetic fields to heat metal pots and pans directly, instead of using a gas flame or a resistive heating element. Induction cooking uses less power than other electrical methods of heating food, making it a desirable option for space, where power is limited.

“The technology is extremely efficient if done correctly,” said George Sadler, chief scientist at IFS. “Compared to other elements, it’s kind of winner-winner-chicken-dinner.”

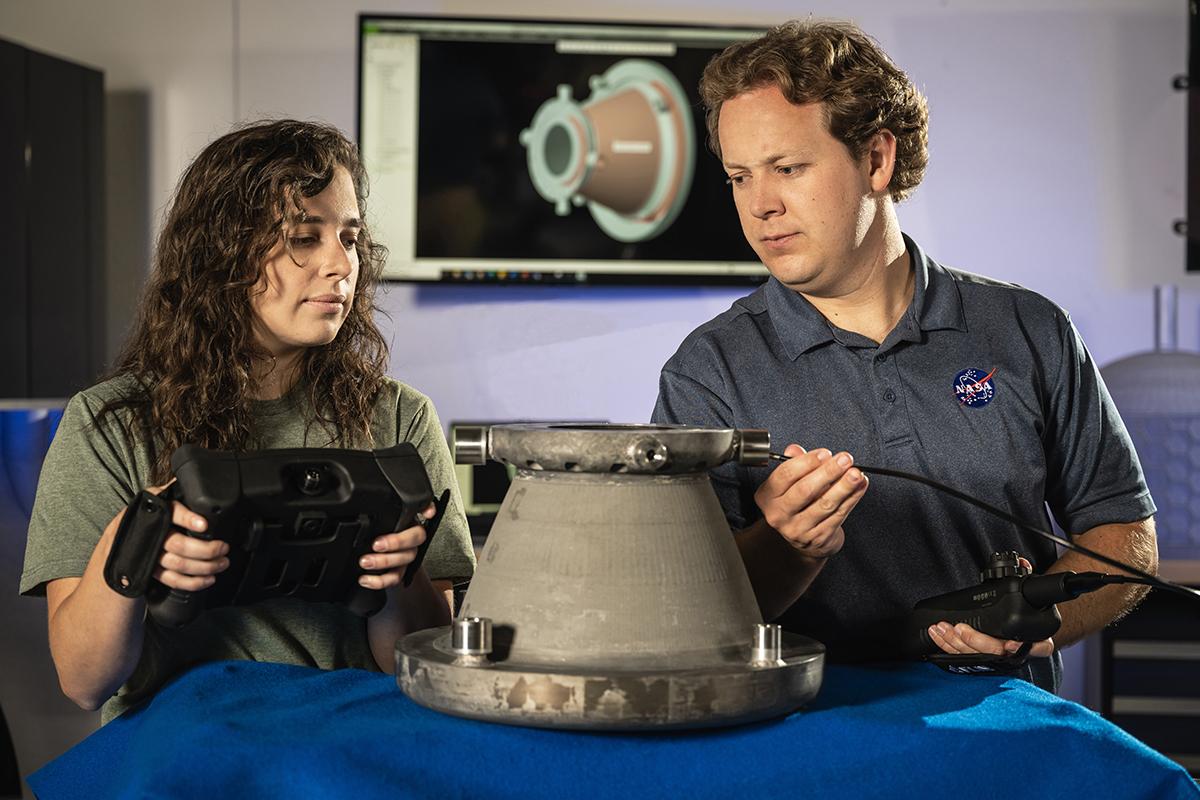

Throughout the course of the Phase II SBIR the company consulted with NASA scientists to work out the physics of using induction to make food for astronauts. The process resulted in a new coil design that could put more power more efficiently into the system than the induction heaters found in home kitchen stoves. A secondary development from the program was a method of removing oxygen from food container materials to further preserve the contents, another step to ensuring astronauts eat well.

While the SBIR was largely exploratory in nature and ultimately resulted in no developments used by NASA, it had clear benefits for the company. IFS was able to parlay the NASA experience into building out both of the explored technologies. The company continued to develop them with further funding from the U.S. Department of Agriculture, and soon IFS was able to pivot towards a whole new market.

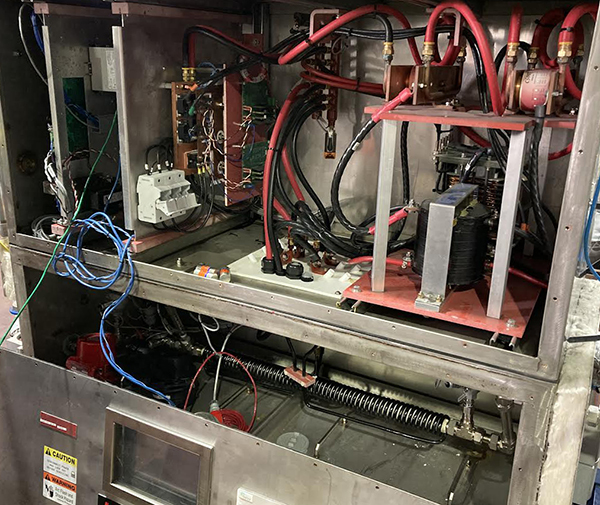

Today, IFS’s primary business is constructing large-scale induction heaters for industrial applications such as food manufacturing. Most industrial heaters use steam heating, which requires enormous amounts of energy, but Sadler says the IFS technology is far more efficient at transforming electricity into heat. Ultimately, Sadler credits the help he received from NASA scientists with getting the company off the ground.

“From building my first inductive heater to all the theoretical calculations I needed to build it at scale, I couldn’t have done it without the NASA connection,” Sadler said.

The heaters that Induction Food Systems builds are used for more than just food production. This system for processing chemical products is one of many commercial offerings the company makes. Credit: Induction Food Systems inc.

NASA has explored the possibility of long-term lunar habitation since first setting foot on the Moon. To have a permanent presence on the Moon would require sustaining crew members for months on end. Exploring ways to preserve and make food for these kinds of missions allowed Induction Food Systems to build its industrial induction heating solutions. Credit: NASA