Aircraft Ducting

As part of their technology transfer programs, NASA centers frequently provide assistance to industrial firms who request it, for example, analysis of a new product design, help in solving manufacturing problems, or product testing in specialized types of facilities that are not available commercially. In many cases, NASA's work results in improvements to the product.

An example of a company that benefited from such assistance is Templeman Industries' TI Aerospace Systems, Inc., North Chicago, Illinois, a manufacturer of composite ducting for aircraft.

TI had developed a composite environmental air duct, known as the Ultra-Seal Ducting System™, that offers a 50 percent weight reduction in comparison with existing metallic ducting. The ducting is intended primarily for commercial aircraft, but it also has utility in a number of military applications.

TI had to assure that the air duct design would meet environmental and cyclic stress specifications, but the company was unable to find a commercial firm with adequate test capabilities. TI turned to Marshall Space Flight Center (MSFC) and the center's Component Test Branch of the Propulsion Laboratory agreed to conduct a structural evaluation.

MSFC put the duct system through tens of thousands of cycles of pressure and leakage tests that were collectively equivalent to 86 years of aircraft takeoffs and landings; the ducting performed satisfactorily. The system is now in production and in use by aircraft manufacturers, among them the two largest U.S. commercial jetliner builders, Boeing Commercial Airplane Group and McDonnell Douglas Corporation.

Ultra-Seal Ducting System is a trademark of Templeman Industries.

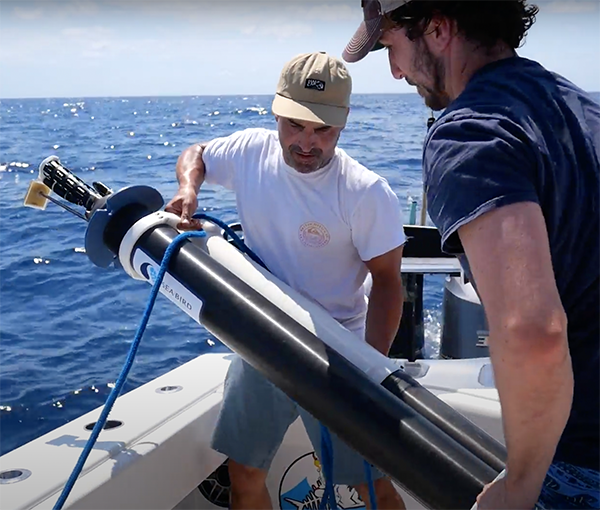

Templeman Industries' J.B. Templeman (left) and Scott Templeman conduct a quality control test on an Ultra-Seal Duct component.

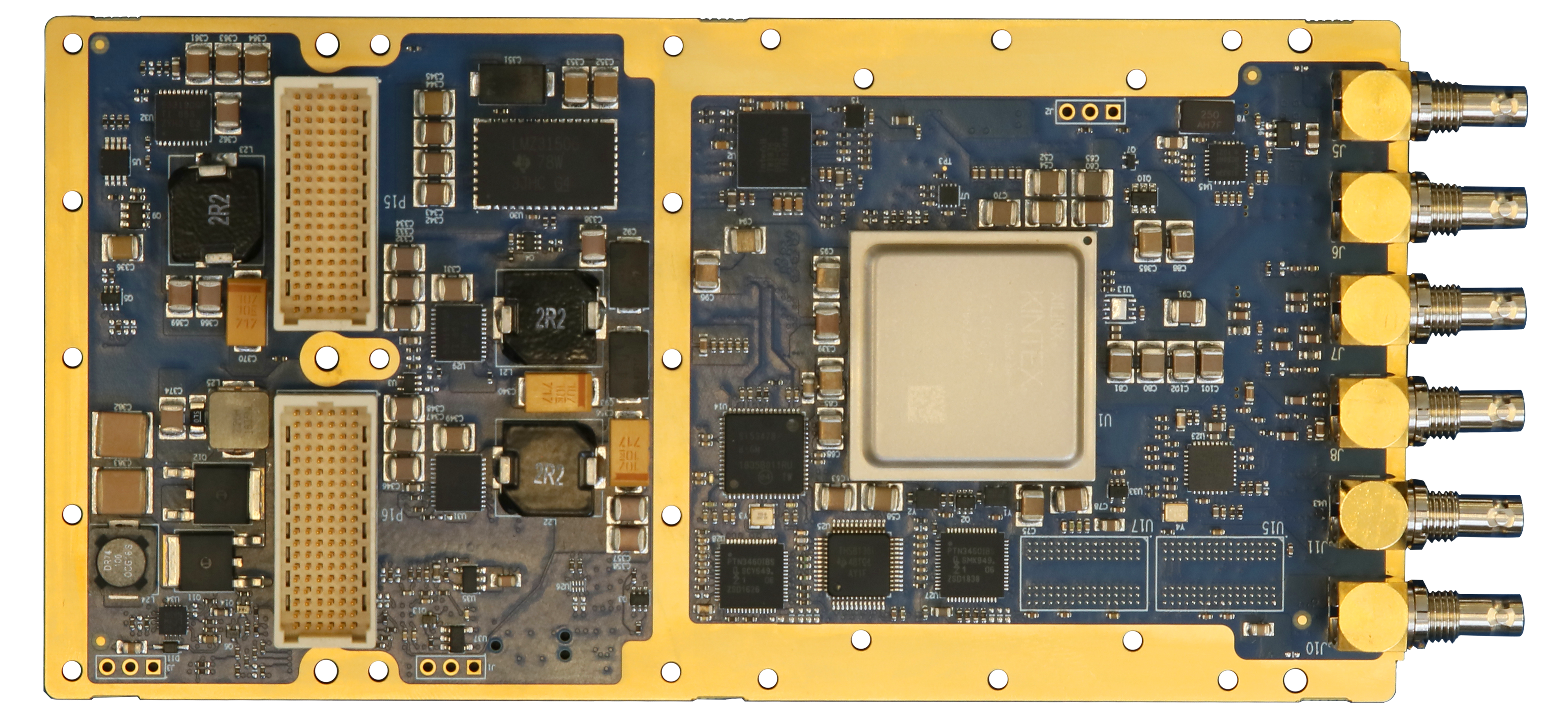

A proprietary casting technique allows fabrication of small and intricate yet high performing Ultra-Seal Duct parts.