Commercial Sales Flow from NASA Valves

Subheadline

Valves developed for NASA programs meet needs of commercial space, other industries

Founded during World War II, Marotta Controls of Montville, New Jersey, started out designing valves for some of the U.S. military’s first liquid-propellant rockets, making the company an obvious fit when NASA started looking for valve suppliers years later. Marotta components have now been integral to every major rocket and crew vehicle in NASA’s history.

Today, however, there are many more players in space travel, meaning the company’s early leap into space technology is paying off with abundant commercial contracts. “During the Mercury and Apollo days, we were making a handful of those components, whereas now, there are so many spaceflights happening we’re manufacturing thousands per year,” said Brian Ippolitto, senior director of business development for Marotta’s space business unit.

Among the valves Marotta developed for NASA programs and now sells commercially are a pair that trace their lineage to early NASA spacecraft, said Ippolitto. The MV100X and MV524LT were further refined for the Commercial Resupply Services program, through which NASA helped fund the development of several private spacecraft to carry supplies to the International Space Station. Marotta expanded the temperature range for both valves to meet commercial resupply needs. Ippolitto said commercial space companies have now used the MV100X in small thrusters that shift a craft’s orientation in space, while the MV524LT is a higher-flow valve used commercially to control flows from pressurized tanks.

Two valves the company developed for the Commercial Crew Program are also now flying on other commercial spacecraft, Ippolitto said. Under Commercial Crew, NASA helped fund the development of spacecraft to ferry astronauts to and from the space station. As a subcontractor, Marotta created the negative pressure relief valve and the MFV400 electronic pressure regulator. The latter was developed for an in-flight abort system, where it will funnel highly pressurized gases into thrusters that can kick a crew vehicle free of a rocket. This valve now allows a commercial lunar lander to save space with a small, extremely high-pressure fuel tank. And the negative pressure relief valve allows air into a spacecraft during atmospheric reentry, preventing it from collapsing under atmospheric pressure. Ippolitto said other companies are now using it for their own “things that are coming back to Earth and need to not be crushed.”

He said Marotta now has components on every U.S. launch vehicle, with sales to space companies accounting for around a fourth of the company’s revenue.

Jimmy Moore, engineer with the Valves, Actuators, and Ducts Branch at Marshall Space Flight Center in Huntsville, Alabama, said the ultimate goal of the commercial crew and commercial cargo programs is to help companies establish a business model for space travel, with NASA as a customer. “But there’s also the effect of suppliers like Marotta having to push the envelope, and now they’ve got a bigger catalog of offerings,” he said, adding that all these developments benefit the commercial space industry and, ultimately, NASA.

Designing for high pressures and other rigors of space travel has opened other doors for Marotta, Ippolitto said. Customers in petroleum drilling deal with harsh environments, and microchip manufacturers uses high-pressure gases in cleaning and manufacturing processes. Several of these companies buy Marotta products incorporating elements the company developed for space.

“It’s about high temperatures, nasty fluids, demanding applications that can’t fail,” Ippolitto said. “You can’t pick up something at your local big-box store that’s going to have similar quality.”

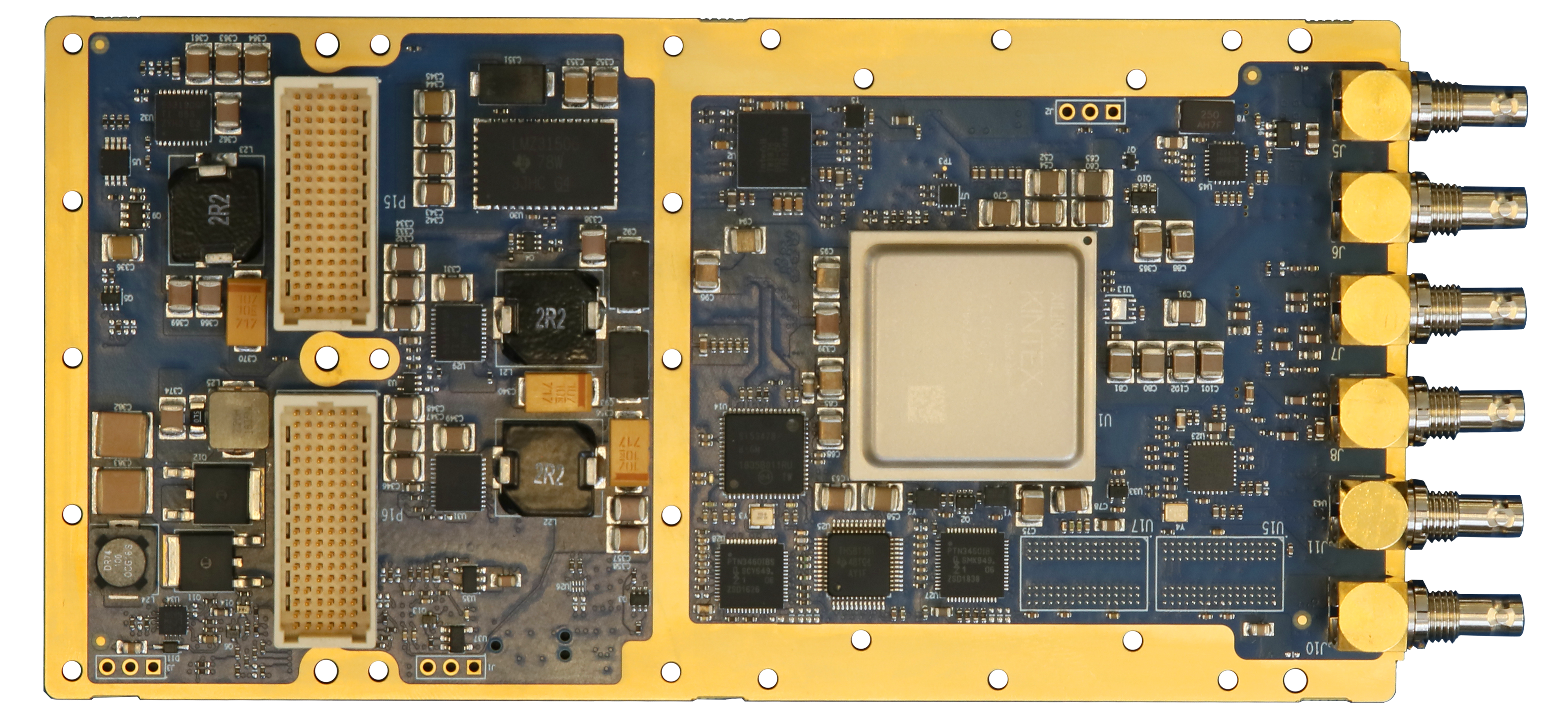

Marotta Controls developed these valves as a subcontractor to NASA’s Commercial Resupply Services and Commercial Crew programs and now sells them to other commercial launchers. Clockwise from top left: The MFV400 electronic pressure regulator is now on a commercial lunar lander. The PRV15B negative pressure relief valve prevents capsules from being crushed on atmospheric reentry. The MV100X is used in small thrusters to adjust spacecraft orientation. And the MV524 controls flows from pressurized tanks. Credit: Marotta Controls Inc.

Marotta Controls founder Pat Marotta, far right, poses with members of his company and others in front of the Saturn I main booster in 1963. The company has been making specialized components for NASA since the early days of the space agency, a heritage that’s paying off as private companies move into the space industry. Credit: Marotta Controls Inc.