Thin, Light, Flexible Heaters Save Time and Energy

Originating Technology/NASA Contribution

Ice accumulation is a serious safety hazard for aircraft. The presence of ice on airplane surfaces prevents the even flow of air, which increases drag and reduces lift. Ice on wings is especially dangerous during takeoff, when a sheet of ice the thickness of a compact disc can reduce lift by 25 percent or more. Ice accumulated on the tail of an aircraft (a spot often out of the pilot’s sight) can throw off a plane’s balance and force the craft to pitch downward, a phenomenon known as a tail stall.

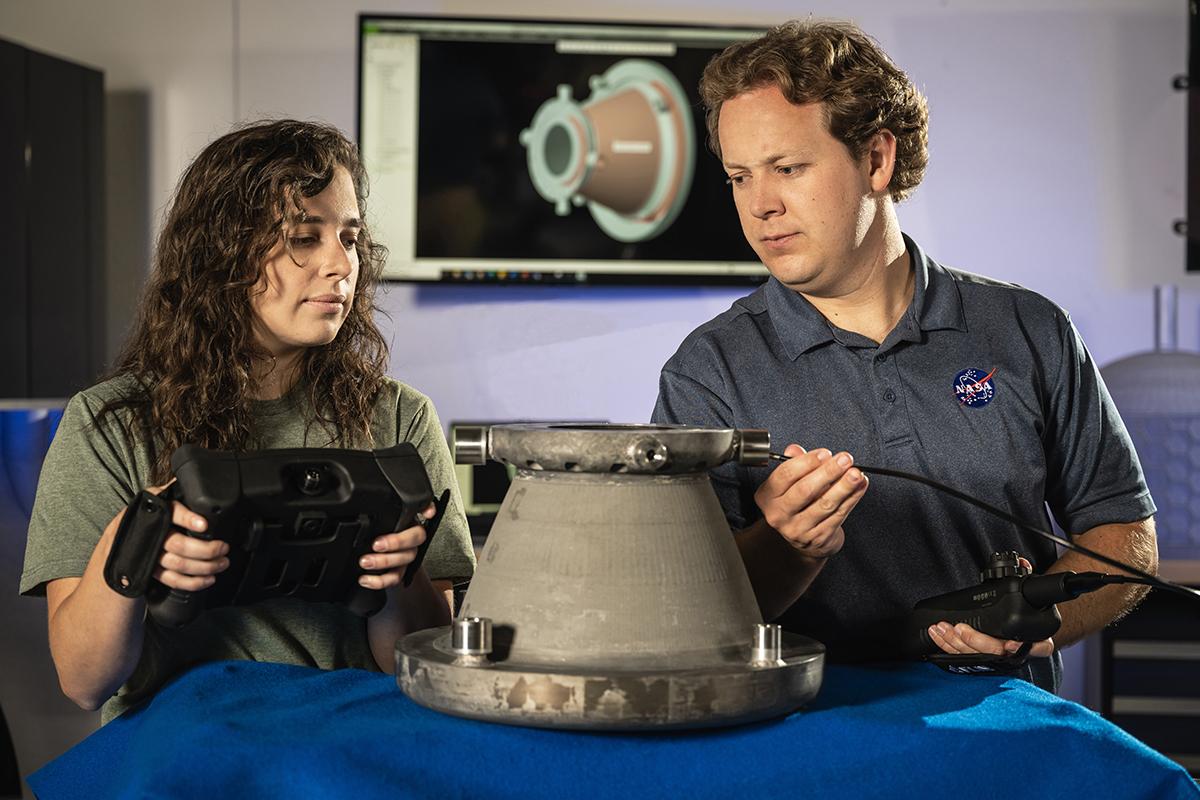

The Icing Branch at NASA’s Glenn Research Center uses the Center’s Icing Research Tunnel (IRT) and Icing Research Aircraft, a DeHavilland Twin Otter twin-engine turboprop aircraft, to research methods for evaluating and simulating the growth of ice on aircraft, the effects that ice may have on aircraft in flight, and the development and effectiveness of various ice protection and detection systems.

Partnership

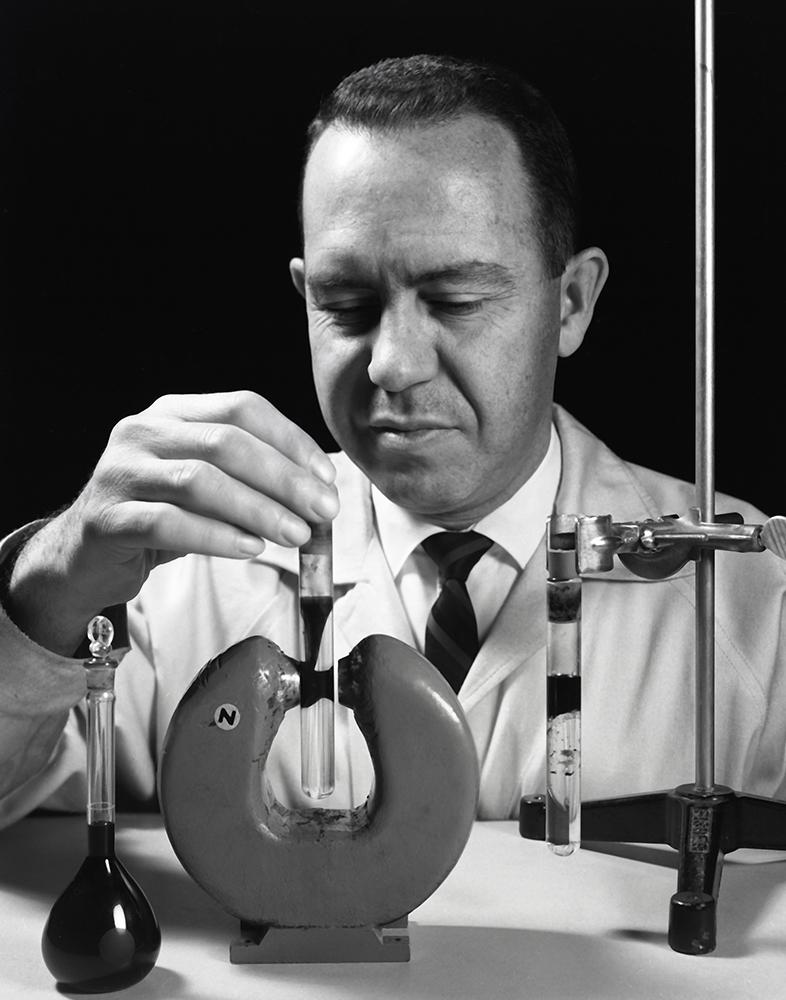

EGC Enterprises Inc. (EGC), of Chardon, Ohio, used the IRT to develop thermoelectric thin-film heater technology to address in-flight icing on aircraft wings. Working with researchers at Glenn and the original equipment manufacturers of aircraft parts, the company tested various thin, flexible, durable, lightweight, and efficient heaters and developed a thin-film heater technology that they discovered can be used in many applications, in addition to being an effective deicer for aircraft.

Product Outcome

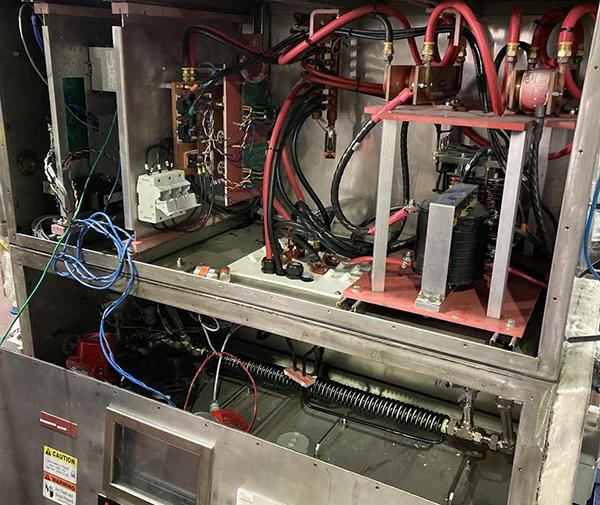

The result of this research was the development of a new thermoelectric heater the company has dubbed the Q•Foil Rapid Response Thin-Film Heater, or Q•Foil, for short. The product meets all criteria for in-flight use and promises great advances in thin-film, rapid response heater technology for a broad range of industrial applications. Primary advantages include time savings, increased efficiency, and improved temperature uniformity.

EGC makes the heaters out of thin layers of varying materials that are bonded to form heater laminates. The inner layer, made of a flexible graphite foil (marketed separately by EGC as ThermaFoil), is electro-thermally conductive and typically laminated between a heat-conducting outer layer, and a protective insulating layer. The inner layer provides full electrical conductivity, eliminating the need for wire elements, metal etchings or heat-conductive fibers. In addition to being readily available and relatively inexpensive, the graphite foil is energy efficient.

Because Q•Foil conducts heat well and can cover a large area, little energy is needed for it to raise the surface temperature to the necessary degree, and it is capable of heat increases as rapid as 100 °F per second if needed, which can translate into savings in time or energy. Designers can configure it to heat an item more quickly or to heat an item to the same temperature as other heaters would, while expending less energy.

Not only does Q•Foil work quickly and efficiently, it is also precise, controllable to within 3 °F. If it is being used for an application that requires different temperature zones, Q•Foil can also be configured to accommodate this within the same heating coil.

While the product is available in a variety of sizes, ranging from 1 square inch to 100-foot lengths, the company notes that it is most efficient over large spaces, as this allows the user to get the most advantage of its unique cost- and energy-saving properties. Thin-film flexibility allows it to be mounted to a variety of objects, and it maintains flexibility through a full range of temperatures. The company has services to assist customers with determining the right dimensions and designs they will require for a specific job.

In addition to wing deicing, EGC has begun looking at the material’s usefulness for applications including cooking griddles, small cabinet heaters, and several laboratory uses.

Q•Foil™ is a trademark, and ThermaFoil® is a registered trademark of EGC Enterprises Inc.

Developed in conjunction with NASA for in-flight aircraft deicing, Q•Foil heaters are now available for a broad range of applications from as small as a single square inch to as large as several square feet, and provide extremely rapid thermal response and even heating for a wide array of temperature ranges.