Nano Goes Magnetic to Attract Big Business

Originating Technology/NASA Contribution

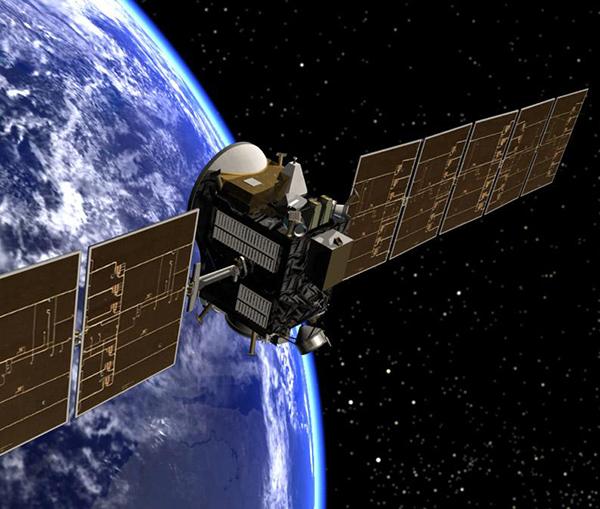

Glenn Research Center has combined state-of-the-art electrical designs with complex, computer-aided analyses to develop some of today’s most advanced power systems, in space and on Earth. The center’s Power and On-Board Propulsion Technology Division is the brain behind many of these power systems. For space, this division builds technologies that help power the International Space Station, the Hubble Space Telescope, and Earth-orbiting satellites. For Earth, it has woven advanced aerospace power concepts into commercial energy applications that include solar and nuclear power generation, battery and fuel cell energy storage, communications and telecommunications satellites, cryocoolers, hybrid and electric vehicles, and heating and air-conditioning systems.

Whether it is energizing the latest space-bound propulsion systems or providing energy for terrestrial purposes, Glenn’s power-generation technology gives NASA the boost it needs to achieve its missions in both realms.

Partnership

In 1999, Inframat Corporation received funding and technical support from Glenn, in the form of Phase I and Phase II Small Business Innovation Research (SBIR) contracts, to fabricate high-frequency, soft magnetic/ceramic nanocomposites in order to advance the magnetic performance of the Space Agency’s electronic, power-generating equipment. According to the Farmington, Connecticut-based company, if these nanocomposites could feasibly be developed, they could yield improved properties over conventional ferrites, including a combination of higher magnetic permeability, higher electrical resistivity, and lower magnetic loss. (Found in electronic devices, a ferrite is any group of magnetic substances that consist essentially of ferric oxide combined with the oxides of one or more metals and have high magnetic permeability and electrical resistivity.) Inframat claimed that, over the past half-century, conventional ferrites have been the only type of magnetic material for high-frequency applications, adding that they perform relatively poorly at high frequencies. These ferrites are also known to deteriorate when exposed to large demagnetizing fields at low temperatures.

Inframat went to work on manufacturing nanocomposite materials with various magnetic frequencies, using a wet-chemical synthesis technique. The intent was to create technology that could have a major impact on NASA’s power management and distribution applications, as well as within the commercial market.

While the technology did not come to fruition during the NASA SBIR effort, Inframat was able to make the most out of what it had learned during this entire experience, as well as the funding it received, to later resolve some outstanding technical issues and create an enabling technology for commercial applications.

Product Outcome

While electronic systems are trending toward multifunctionality and increased miniaturization at higher speeds and lower costs than ever before, they can still have their limitations. For example, current inductive (power) components in a traditional semi-conducting chip can be a major impediment for the mass miniaturization of electronics, due to the fact that conventional, micro-sized, magnetic materials can only be used properly at very low frequencies.

The limitations of conventional magnets become significant in high-frequency applications (above 1 megahertz), because their permeability, or magnetic-quality factor, starts to decrease as frequency increases, thereby increasing their deterioration exponentially.

To transcend these limitations and propel to a new level the manufacturing, cost, weight, performance, and reliability improvements demanded of high-frequency electronic devices and inductors, Inframat has spun off a company called Embedded Nanomagnetics, Inc. This new enterprise is commercializing Inframat’s revolutionary nanocomposite advancements under the brand name M-power. According to Inframat, the M-power brand name is representative of one of the key power advantages of Embedded Nanomagnetics products: “…the fact that they deliver up to 10 times more inductive value and efficiency than conventional magnetic materials of the same size.”

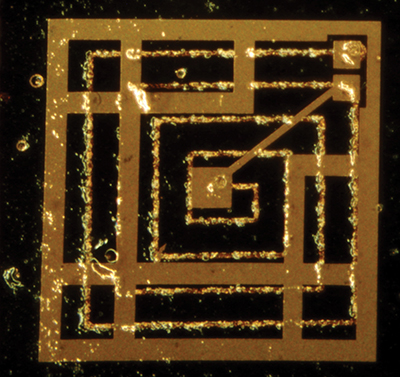

For the designing and manufacturing of M-power nanocomposites, Inframat and Embedded Nanomagnetics have a proprietary process in place that enables extremely dense packing of nanoscale magnetic particles into a magnetic paste or film. When configured as a nanomagnetic paste, for instance, the material is capable of achieving the high-inductance values that are required for embedded power circuit board applications (applications for which high-inductance values cannot be accomplished using thin film techniques). In this case, the paste can simply be silk-screened onto a circuit board. On the other hand, when configured as a thin film, the material can achieve high-inductance values for applications that are dependent on semiconductor wafers, instead of circuit boards.

The M-power magnetic material has demonstrated that it can maintain high permeability with extremely low core loss (loss caused by a magnetization of the core and its resistance to magnetic flux) and excellent electrical properties, even at high frequencies extending into the gigahertz range (1,000 megahertz equals 1 gigahertz). This design possesses soft magnetic properties that Inframat considers “far superior” to those of conventional ferrites, thus, it enables “much greater flexibility” in tailoring magnetic and electric parameters in a wide range of applications.

Device use for M-power materials include: power converters, antennas, broadband filters, sensors, digital packing converters, radiofrequency switches, microwave and millimeter wave circulators, sound-suppressors, hybrid integrated circuits, and semiconductor wafers. These applications cover a broad spectrum of commercial markets, such as telecommunications, computers, consumer electronics, automotives, aerospace, defense, power generation, and industrial operations.

Embedded Nanomagnetics is initially focusing on the electronics, telecommunications, and defense markets, as it has attracted the attention of several market leaders in these industries. One of these leaders, Tagent Corporation, is working to integrate the M-power materials into small, cost-effective radio frequency identification systems intended for fully automated electronic tag reading and item tracking.

Inframat® is a registered trademark of Inframat Corporation.

M-power™ is a trademark of Inframat Corporation.

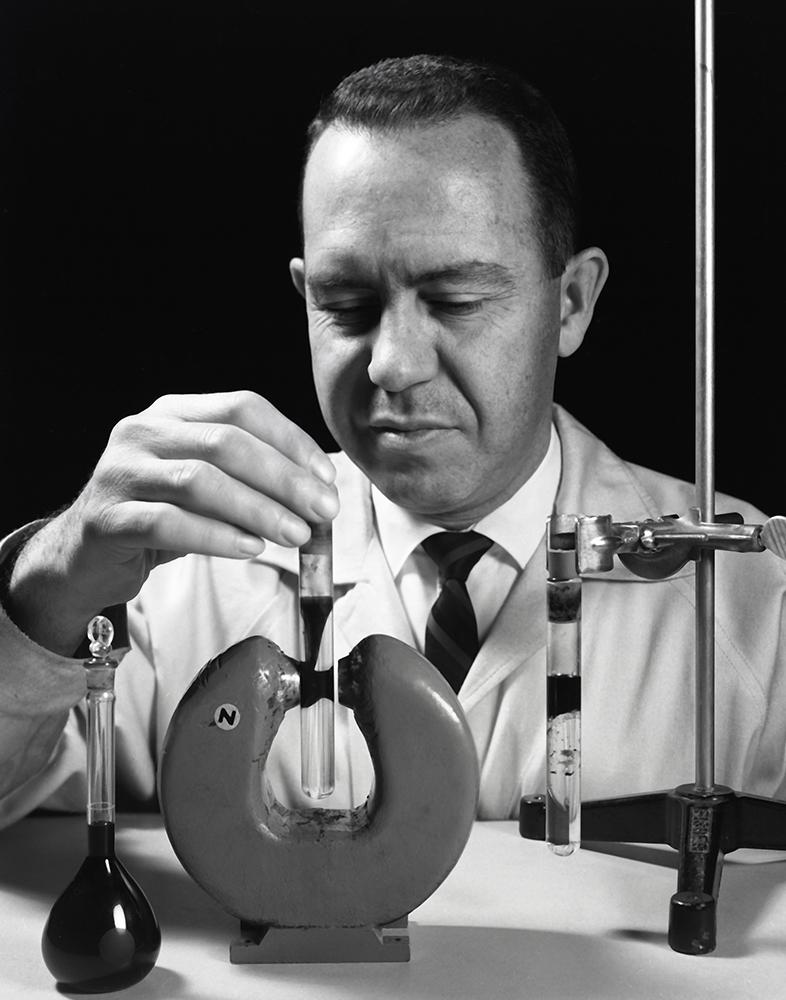

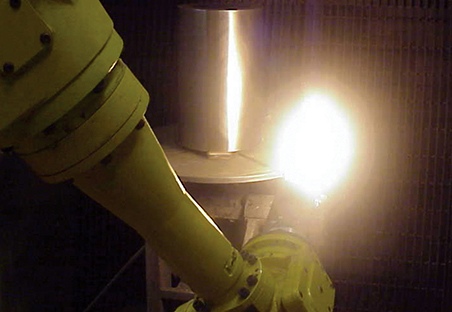

Inframat Corporation is an emerging technology company founded in 1996 to develop nanostructured materials to improve performance and extend the life of coated components used throughout the global infrastructure. These materials include magnetic nanocomposites with superior magnetic properties and a plasma spray nanocoating, seen here being applied by a spray gun onto a steel roller.

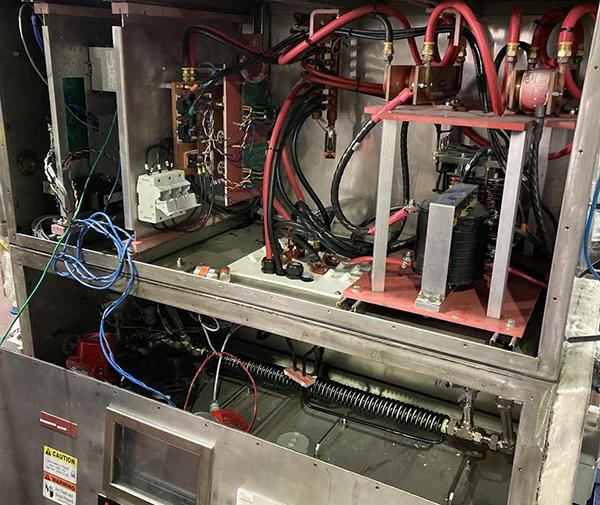

Telecommunications is a part of Embedded Nanomagnetics, Inc.’s initial market focus. Pictured here is a microtransformer for DC-DC converters in cell phone applications. Image courtesy of Drs. P.M. Raj and Lixi Wan.

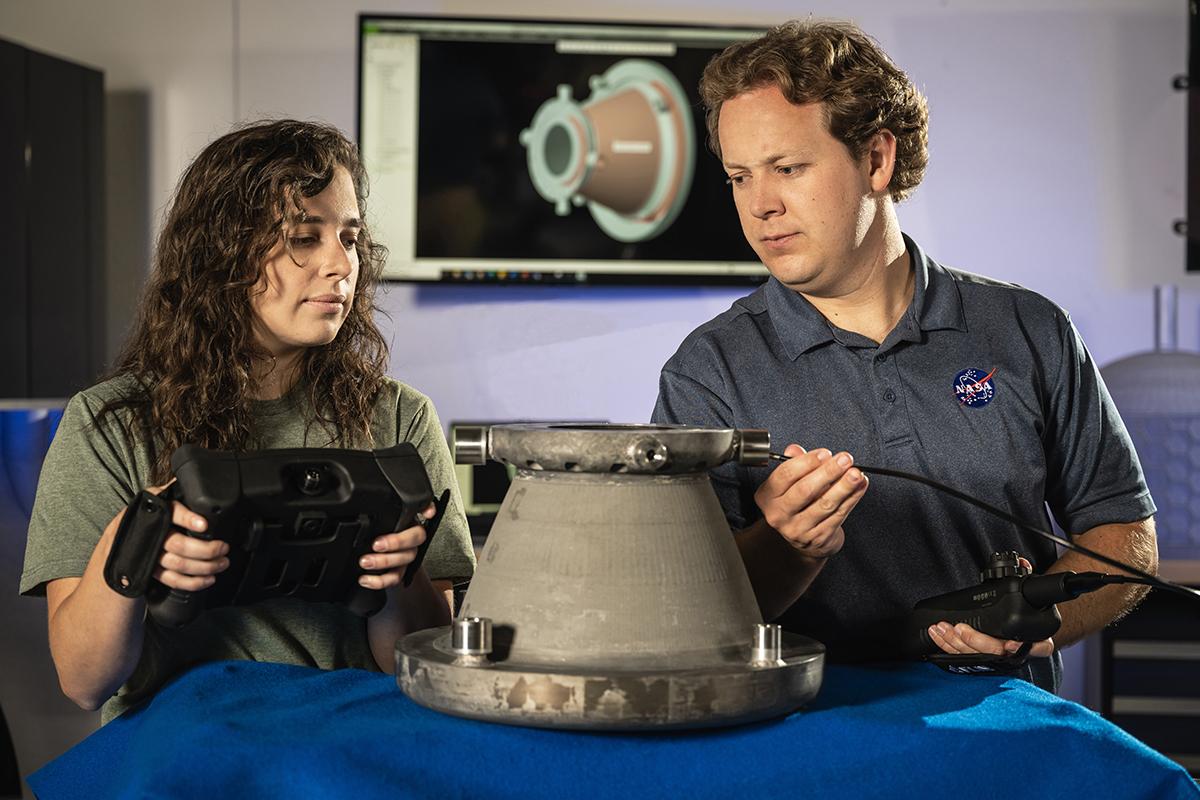

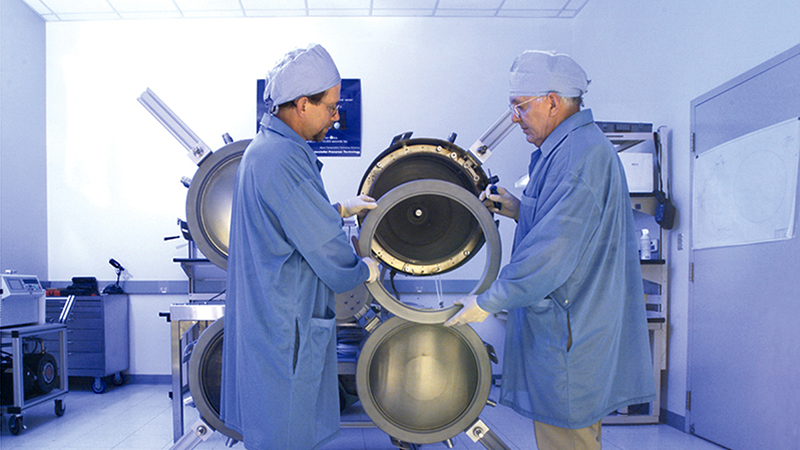

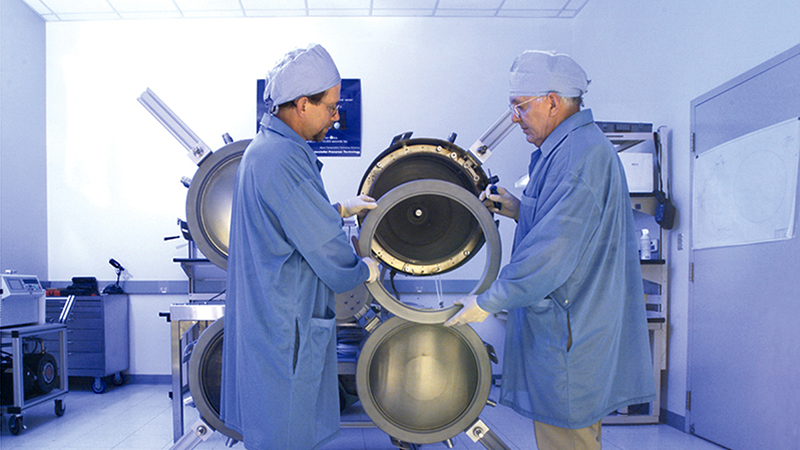

Glenn Research Center engineers assemble a NASA Evolutionary Xenon Thruster (NEXT) for testing. This thruster is a next-generation propulsion system that could revolutionize the way NASA sends science missions deep into the solar system. The thruster is built to use xenon gas and electrical power to drive spacecraft.