Fresh Veggies From Space

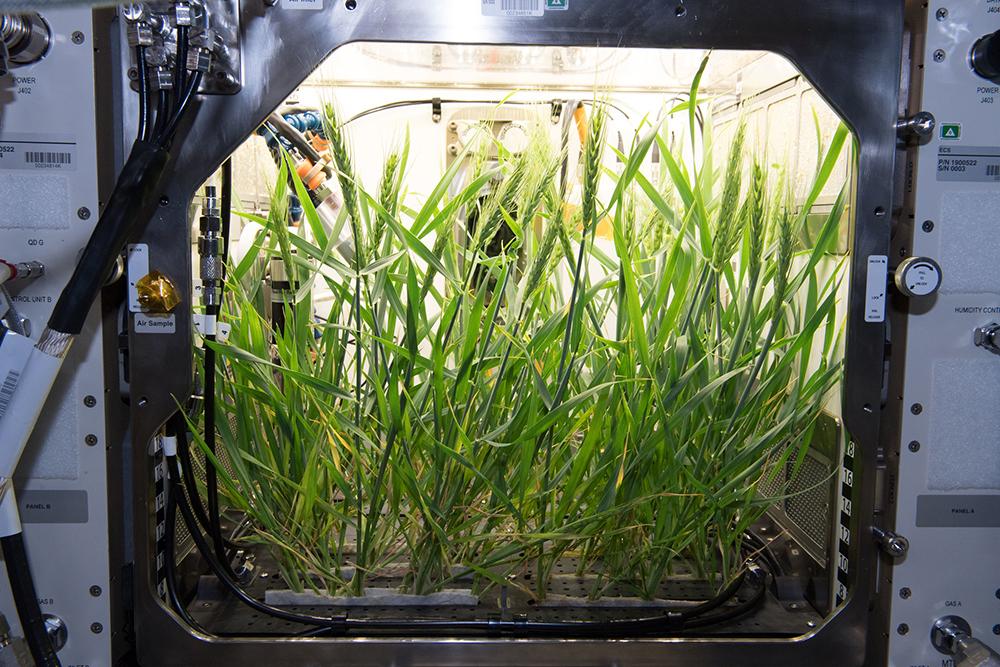

Professor Marc Anderson of the University of Wisconsin-Madison developed a technology for use in plant-growth experiments aboard the Space Shuttle. The University isto the Wisconsin Center for Space Automation and Robotics (WCSAR), a NASA Commercial Space Center sponsored by the Space Product Development Office at NASA's Marshall Space Flight Center. Anderson's research and WCSAR's technology were funded by NASA and resulted in a joint technology licensed to KES Science and Technology, Inc., of Atlanta, Georgia. This transfer of space-age technology resulted in the creation of a new plant-saving product.

Ethylene is a natural hormone that causes plant spoilage and premature withering if present in excess amounts. Produced by plants, it acts as a chemical cue that tells plants to begin ripening. It is critical to remove ethylene from enclosed plant-growth environments, such as those for growing in space, because high concentration levels can be detrimental to the plants. WCSAR, in conjunction with Anderson's technology, created an ethylene scrubber for plant growth chambers. This innovation presents commercial benefits for the food industry in the form of a new device, named Bio-KES.

Incorporating the WSCAR filter system, Bio-KES removes ethylene and helps to prevent spoilage. The system's fan draws in air and passes it over pellets treated with titanium dioxide. The titanium dioxide works as a catalyst to break down the ethylene into carbon dioxide and water vapor. This change is triggered by photocatalysis, a process that uses ultraviolet light to activate the titanium particles. The by-products of carbon dioxide and water vapor are then recirculated back into the storage or display area.

The unique process of the Bio-KES systems has advantages over other ethylene removal systems. Most systems simply oxidize the ethylene in the air with an oxidant such as potassium permanganate, and consequently, require frequent maintenance to remove exhausted oxidant pellets. Bio-KES breaks down ethylene catalytically, thereby eliminating build-up, so the system is almost maintenance-free. Because air continuously passes through the device, Bio-KES removes approximately 99 percent of the present ethylene and concentrations are unable to reach harmful levels.

The use of ultraviolet light is another advantage, since it is proven to reduce the presence of mold, bacteria, and odor from produce storage areas. Other devices do not typically involve ultraviolet light.

Ethylene accounts for up to 10 percent of produce losses and 5 percent of flower losses. Using Bio-KES in storage rooms and displays will increase the shelf life of perishable foods by more than one week, drastically reducing the costs associated with discarded rotten foods and flowers. The savings could potentially be passed on to consumers. According to KES president, John Hayman, Jr., "I couldn't even begin to give you the billions of tons of food that can be given, or handed to the end user, in a usable state, rather than something that the grocery stores or the commercial enterprises have to throw out."

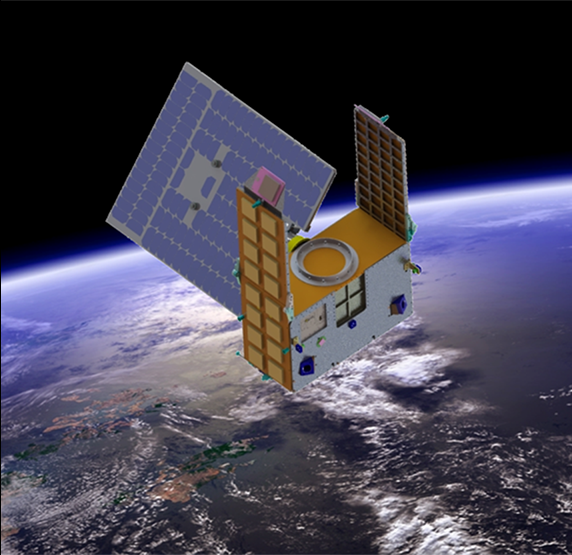

A special plant-growth chamber constructed with this technology has flown on numerous shuttle missions. For NASA, the device means that astronauts can conduct commercial agricultural research in space. Eventually, it may also help to grow food in space and keep it fresh longer. This could lead to less packaged food being taken aboard missions since it could be cultivated in an ethylene-free environment.

The Bio-KES system uses NASA technology to remove ethylene gas and airborne pathogens from small storage areas, as well as floral and produce display cases.