Here's a Switch

Coming face to face with a panel full of switches and dials in a small, general aviation aircraft cockpit is more than an eyeful. It can be dangerous as well.

Modern aircraft have a multitude of systems and controls blended into what is known as the instrument panel. Advancements in aviation technology have driven the panel's shape and size. But in many ways, such avionics improvements can make the instrument panel cluttered and harder to expand. More importantly, a jungle of devices and the addition of new systems can reduce the safety of flying conditions. The causes of numerous aviation accidents have been traced to unrecognized or improperly interpreted instrument readouts.

According to research, progressively deteriorating conditions, such as weather, instrument failure, and aircraft system malfunctions, are significant causes in general aviation accidents. In any of those cases, problems go unrecognized, are not understood, or are mishandled by the pilot. Problems predominantly begin as small symptoms that go undetected by the pilot, then evolve into larger problems, with potentially dangerous outcomes. Such problems could possibly be averted with an intelligent human factors-engineered pilot alerting system.

Through a NASA Advanced General Aviation Transport Experiments (AGATE) competitive award negotiated by the Langley Research Center, Mod Works, Inc., of Punta Gorda, Florida, has applied human factors engineering to the instrument panel to optimize human/airplane interaction. The result is the "Smart Panel," offered by Mod Works to reduce pilot workload and increase flight safety.

Mod Works has designed an instrument panel for installation in certified aircraft offering features geared toward simplification in cockpit design for human factors. The affordable panel is an easy retrofit into aircraft, updates older, confusing panels to present day standards, and reduces the number of control panel instruments. Ergonomically designed, the panel reduces pilot workload and eyestrain, and is completely and quickly removable for repair or maintenance.

In addition, the Mod Works "Smart Panel" includes switches, circuit breakers, and the VM1000 engine monitoring system, developed by Vision Microsystems, Inc.. The VM1000 is considered by pilots to be the most advanced engine monitoring system available, where instruments are combined into one display.

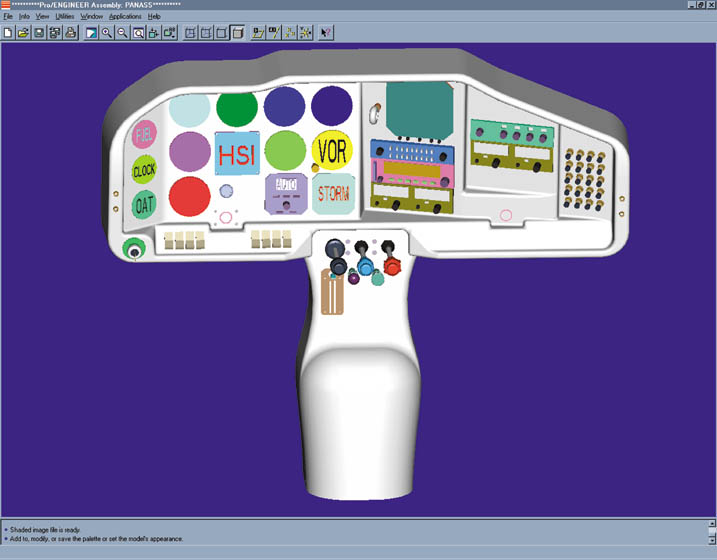

Mod Works started work on the new panel concept by creating a 3-D computer model of the interior structure of a popular general aviation aircraft. A database was then established of instruments and avionics currently on the market. By placing the desired equipment in the 3-D space of the interior model, engineers at the company were able to optimize location, viewing angle, hand access, and visibility. The information depicted on each instrument was categorized by necessity and function. Human factors engineering drove the panel design, rather than evolution or space availability.

From there, Mod Works transferred 3-D math data to fabricated instrument panels. After two years of evaluation and then certification, Mod Works introduced the aircraft panel for commercial sale.

The Mod Works cockpit design innovation integrates emerging and commercially available software and hardware technologies now in the marketplace or under development by avionics vendors. By using commercially available products, risk and cost of the general aviation end product can be controlled.

Mod Works is confident that a general aviation market exists for human factors-engineered cockpits. The need for reduced pilot workload and enhanced intuitive decision-making, tied to the human factors engineering know-how of Mod Works, makes for improved flight safety. This capability, the firm believes, has excellent market potential since no such product is available in the retrofit general aviation market.

The company started work on its instrument panel concept by creating a 3-D computer model.

Mod Works, Inc., has designed an instrument panel that offers features geared toward simplification in cockpit design.