Infrared Fiber Optic Sensors

Remote sampling of hazardous environments or judging the quality of paper, textiles, and composites on a production line are among the duties of an innovative infrared fiber optic probe.

The creation of remote infrared fiber optic sensing systems by Sensiv, Inc. of Waltham, Massachusetts was assisted by successive years of Small Business Innovation Research (SBIR) funding from Langley Research Center. Sensiv is a joint venture between Foster-Miller, Inc. of Waltham and Isorad, Ltd. of Israel.

NASA's SBIR interest in infrared, fiber optic sensor technology was geared to monitoring the curing cycles of advanced composite materials. Foster-Miller was awarded Phase I and Phase II SBIR contracts to develop the In-Situ Fiber Optic Polymer Reaction Monitor that could lead to higher yields and lower costs in complex composite manufacturing. These funds helped in the fabrication of an infrared, fiber optic sensor to track the molecular vibrational characteristics of a composite part while it is being cured.

The inventive sensor utilizes Fourier Transform Infrared (FTIR) spectroscopy. This is a widely accepted laboratory technique for performing precise compositional analysis in solids, liquids, and gases. A major drawback, however, was the need for expensive sample holding accessories and labor intensive sample preparation. These barriers confined use of the method to the laboratory.

Placing this highly accurate FTIR analytical tool directly at a processing site or production line is central to Sensiv's remote infrared fiber optic sensing system. This allows more rapid study of defects and field samples, eliminating the time and cost of returning samples to a central laboratory.

Foster-Miller ingenuity allowed infrared transmitting optical fibers to combine with FTIR spectroscopy to enable remote sensing. How it works is straightforward. The optical fiber gathers data via reflected light, which is transmitted to the spectrometer through a cable. Flexible fiber optic cables permit the probe to reach difficult to get at samples. The spectrometer may be over 15 feet away from the processing line or sample. Measurements can be taken every few seconds depending on the type of process being monitored. Spectra are gathered by computer for analysis.

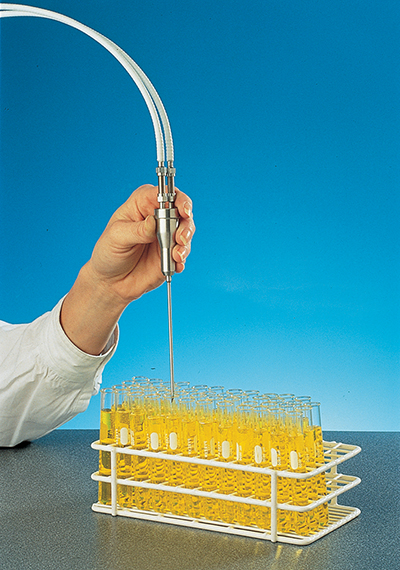

Sensiv probes operate in the mid-infrared range of the spectrum, although modifications to the instrument also permits its use in the near-infrared region. The Sensiv needle-probe is built to be placed in a liquid or powder and analyze the chemicals in the mixture. The small size of a needle-probe, for example, is ideal to get samples such as circuit board components, recessed sample areas, skin, small sample containers and large samples such as metal parts and forensic samples.

The pencil grip-like design of the needle-probe permits the acquisition of excellent quality spectra from samples in many different orientations.

Probes, cables and spectrometers used in the system can be customized to meet specific process needs of a customer. This remote, real-time analytic capacity makes the probe useful for chemical and environmental purposes, as well as in medical applications.

Other applications of the probe system include food processing control; combustion control in furnaces; maintenance problem solving; and numerous defense industry applications such as cure monitoring of solid rocket motor propellants.

Sensiv is working with Spectra-Tech Inc. of Shelton, Connecticut to commercially distribute the FTIR probe system in the United States and overseas.

Fiber optic sensing system by Sensiv has made chemical, environmental and biological sampling in remote and difficult areas possible. The NASA spinoff is rooted in space research that studied how best to monitor the curing of composite materials.