Getting the Gold Treatment

Epner Technology, Inc., of Brooklyn, New York, has a golden reputation at NASA's Goddard Space Flight Center. In 1996, the company first partnered with Goddard to gold-coat a telescope mirror for use on the Mars Global Surveyor. The mirror, known as the Mars Orbiter Laser Altimeter (MOLA), functioned as part of a laser device to chart Mar's topography. Epner Technology's LaserGold® process was used on the mirror to give it the sensitivity necessary for the operation. The success of this project led Goddard to call upon Epner's expertise again to work on the Vegetation Canopy Lidar (VCL) mirror. This partnership resulted in new commercial applications for the LaserGold process in the automotive industry.

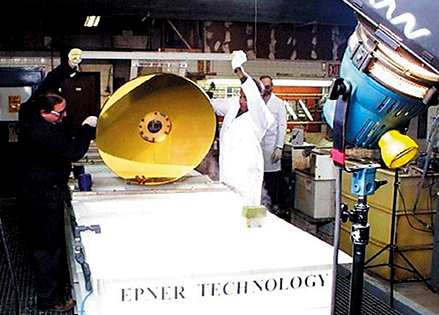

The VCL mirror will orbit the Earth in 2003 as part of NASA's Earth System Science Pathfinder (ESSP) program. Intended to map the Earth's surface in the same way that the MOLA mapped Mars, the VCL mirror presented a unique challenge to Epner because of its size and worth. With a 0.9-meter diameter, the mirror was too large for Epner's plating tanks. Made of beryllium, an expensive but ideal material for space optics, the mirror had a value of more than 1 million dollars. The company considered using the mirror itself as its own plating tank since it had a slight dish shape, but the danger to the mirror for such an experiment was deemed too great. Given the mirror's worth, the Epner team needed to find a solution that would be effective without risking the mirror's safety.

The safest method was to build a facility large enough to accommodate the VCL mirror, so that it could be plated the same way as the MOLA mirror. The greatest roadblock was the cost. NASA did not have the budget to cover the cost of the setup necessary to gold-coat a mirror of this size, in addition to the cleaners, acid dips, nickel plating, gold strike, LaserGold plate, and rinse steps involved. With the additional cost of the gold needed to charge the tanks and the necessary rehearsal time on a dummy mirror, it did not look like plating the VCL mirror would be possible.

Epner recognized a commercial opportunity that would make the project lucrative. A few years earlier, Epner explored the possibility of selling LaserGold-coated reflectors to the automotive industry. The company, thwarted by the size of the oven panels that are used in its production paint drying ovens, did not have equipment large enough to cost effectively handle the plating of the stainless steel panels. Seeing a chance to renew this effort, David Epner, owner and chief executive officer of the company, stated, "If we could come out of this project with a production capability to handle large parts, whole new markets would be open to us...not the least of which was the automotive industry." As a result of this new vision, Epner Technologies and Goddard entered into an agreement by which NASA would fund the facility needed to do the gold-plating, and the company would cover all other costs as part of its internal research and development.

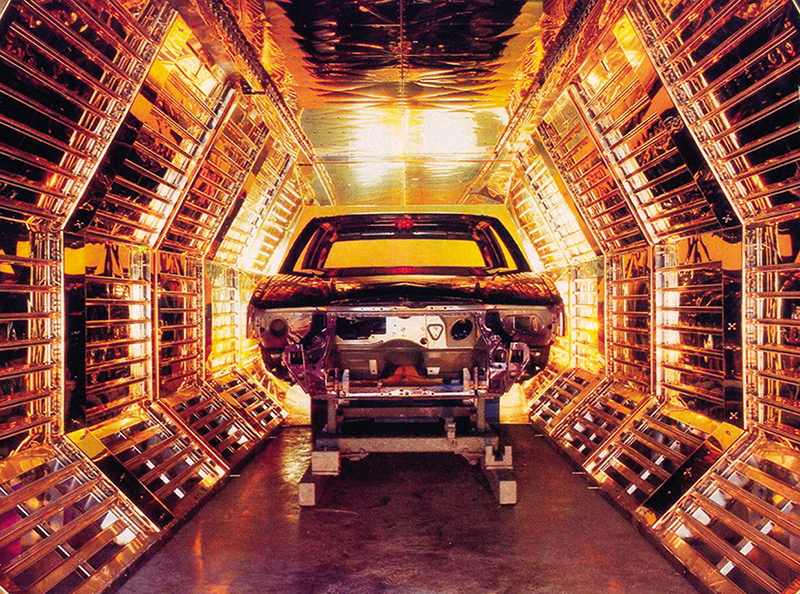

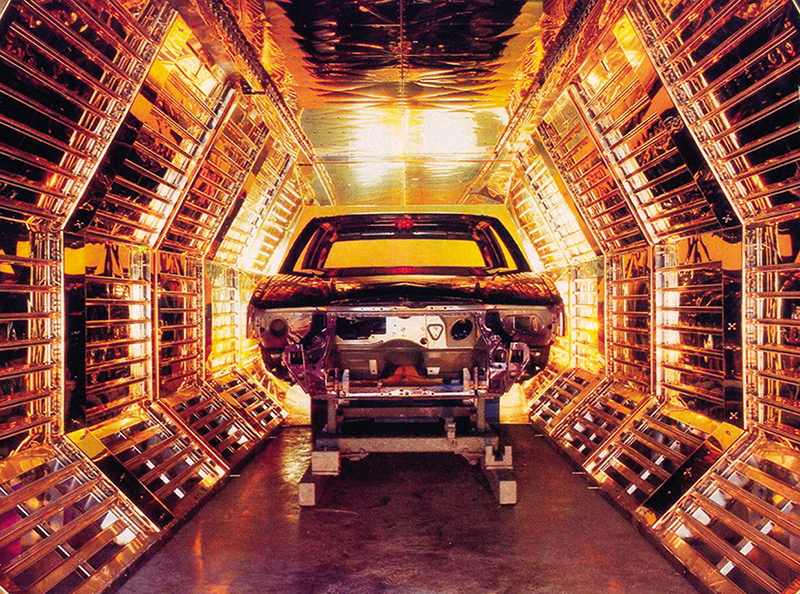

The VCL mirror project proceeded successfully, fulfilling Goddard's needs and leaving Epner with a new facility to provide LaserGold for the automotive industry. This new capability means increased energy savings and improvements in both quality and production time for BMW Manufacturing Corporation of Spartanburg, South Carolina, and Cadillac of Detroit, Michigan, as well as other manufacturers who have implemented Epner Technology's LaserGold process.

LaserGold® is a registered trademark of Epner Technology, Inc.

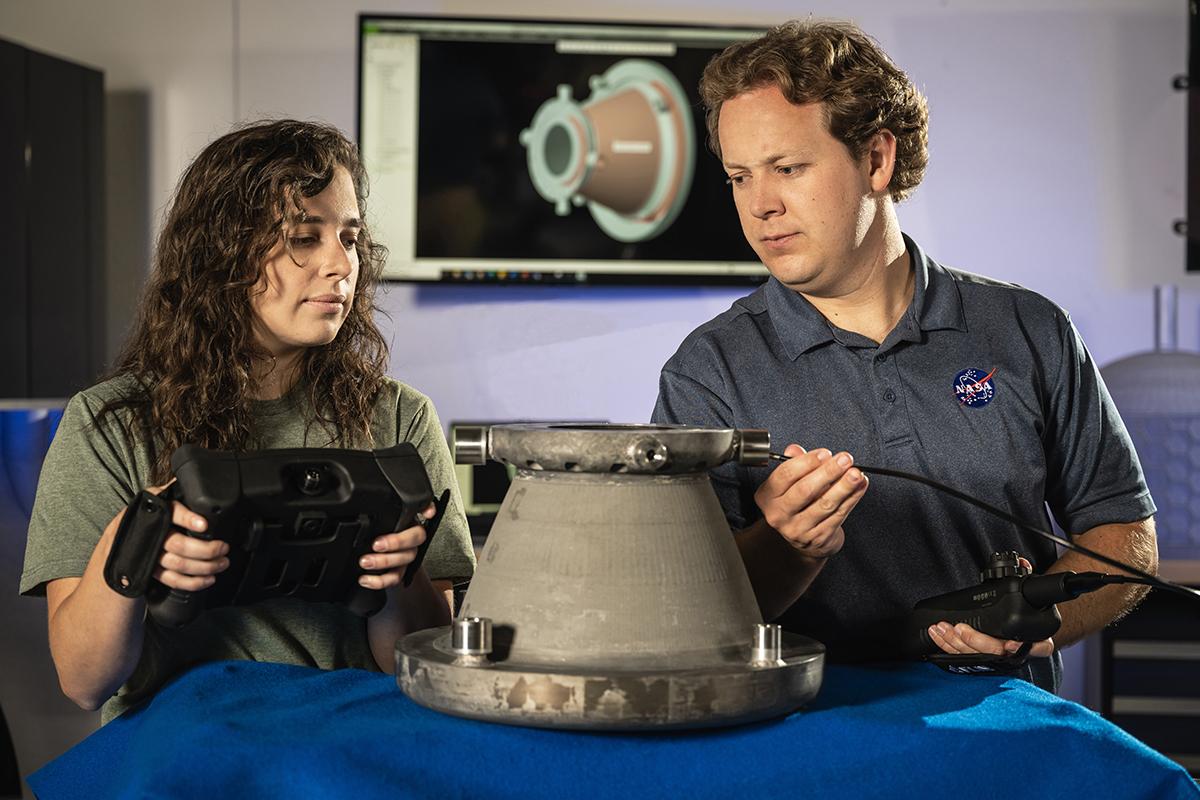

NASA's Vegetation Canopy Lidar mirror was carefully gold-coated to provide it with the sensitivity necessary for operation

Epner Technology’s new facility brought the company’s LaserGold® process to the automotive industry.