A New Kind of Curing

A new curing method using automated tape placement (ATP) with electron beam (EB), or e-beam, produces a combination known as in situ e-beam curing. Through a Small Business Innovation Research (SBIR) contract from NASA's Marshall Space Flight Center, Science Research Laboratory, Inc.(SRL), of Somerville, Massachusetts, created the in situ e-beam curing technique, which uses a low-energy electron beam gun to cure various composite materials. The new process is a valuable tool in the aeronautics, aerospace, and automotive industries.

While e-beam curing is not new, SRL's use of a low-energy gun for in situ e-beam curing is truly innovative. One important benefit is the technique's utilization of room temperature curing, which lessens the chance of mismatching the thermal expansion coefficients of different materials. For instance, metals and composites will expand at different rates when heated, but the low-energy e-beam gun reduces the expansion differential. Using a low-energy gun also results in less x-ray shielding, significantly reduced capital costs, reduced facility space, and increased processing capabilities for larger parts. However, using a low-energy gun also means that each tape layer is treated individually because the gun can penetrate only one layer at a time.

Previously, two separate facilities were needed: one for ATP and another for e-beam or autoclave curing. The e-beam gun combines these two steps into one process, leading to the added benefit of potentially faster throughput, since ATP lay-up and the curing process are completed at the same time. Usually, the first step required that the tape or material be laid out, followed by debulking under a vacuum bag. The second step called for the curing by either an autoclave for heat and pressure, or a high-energy e-beam. An autoclave is like a pressure-cooker for materials that need to be hardened, or cured, before they can be used. Typically, using an autoclave can be expensive and time-consuming. Additionally, an autoclave cannot cure parts that are unable to fit inside it. The costs associated with the construction of both an autoclave for the large composite parts presently being designed, and a building to house it, are high. However, the new in situ e-beam curing technique can cure large parts by adding a low-energy e-beam gun to an existing ATP facility; and because this new system cures the material as it is laid, less power is needed.

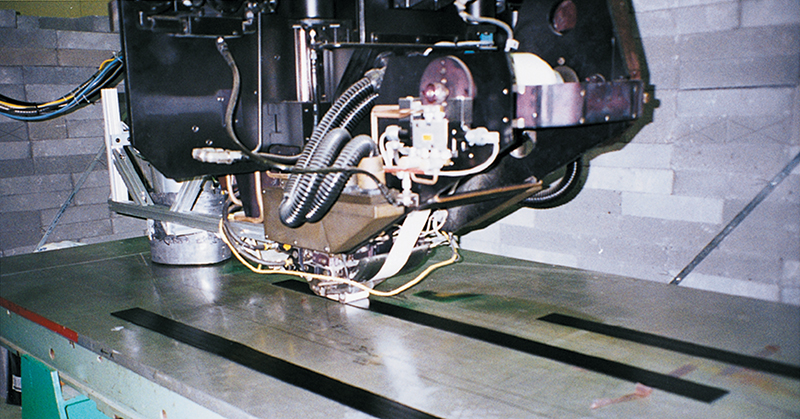

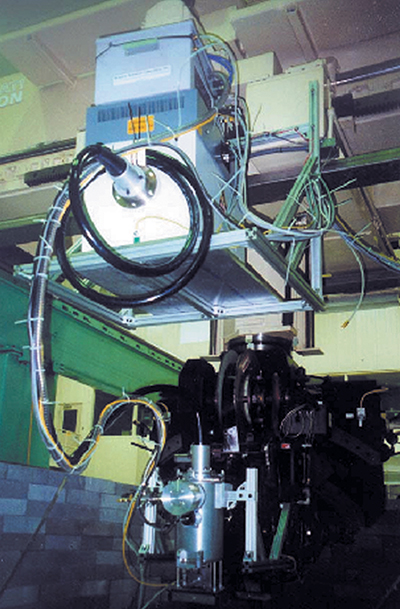

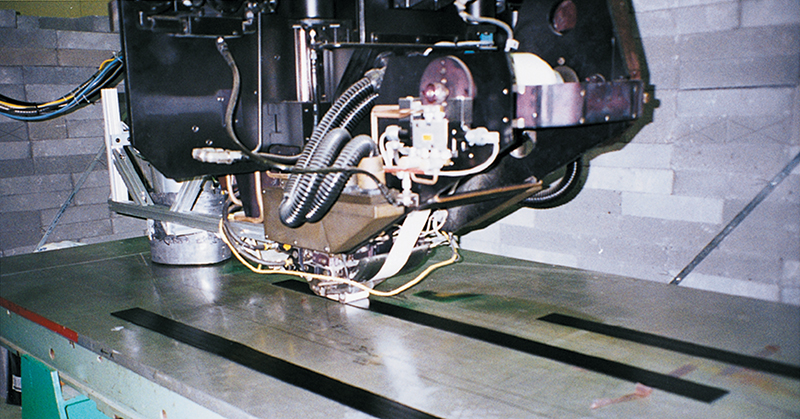

The e-beam gun emits lower energy x-rays, which are more easily shielded than those emitted by previous guns. The low-energy system is relatively portable due to its light weight and small size. The gun weighs about 70 pounds and can be easily mounted on a robotic arm or an ATP head. Furthermore, these convenient developments have not detracted from its capabilities. The gun still delivers electrons with sufficient energy for composite part fabrication and bonding. Since curing is conducted during the placement of tape, a large volume of tape can be placed and cured in only one step.

Keeping with the efficient nature of the new technique, an easily reconfigured x-ray shield is the only other accessory required. Portable shielding is comparatively lightweight and consists of either lead panels on wheeled supports or readily available cement blocks. It is easily added to already existing facilities when the EB system is installed. Portable shielding also contributes to the cost saving features of this product. As much as half of the costs of developing high-energy EB facilities involve the construction of concrete x-ray shielding walls and ceilings. By eliminating the need for high-energy EB facilities, construction costs are significantly reduced.

While primary applications are in the aerospace industry, future uses for the EB-ATP system in the automotive industry are anticipated. Chrysler is experimenting with this technology to develop a concept composite car and may apply the EB curing technology to the manufacture of various automotive parts.

Present users of the EB-ATP in situ curing system are impressed with its flexible and productive nature. In an effort to advance the system, SRL created a spinoff company, Electron Solutions, Inc., which sold and installed a similar electron gun system for the Boeing Radiation Effects Laboratory in Seattle, Washington. Scientists at Marshall are planning on using the in situ e-beam curing system to cure parts used in the construction of rocket fuel tanks for reusable launch vehicles. Using the new product will lead to reduced costs--and not just pennies, but millions of dollars. As SRL continues to improve its system, the company will continue to provide innovative curing options to both NASA and private sector manufacturers.

The electron gun at the bottom center of the picture is mounted to the ATP head, which is black. The e-gun high-voltage power supply is in the top half of the picture, mounted to the crossrail that supports the ATP head and moves it horizontally.

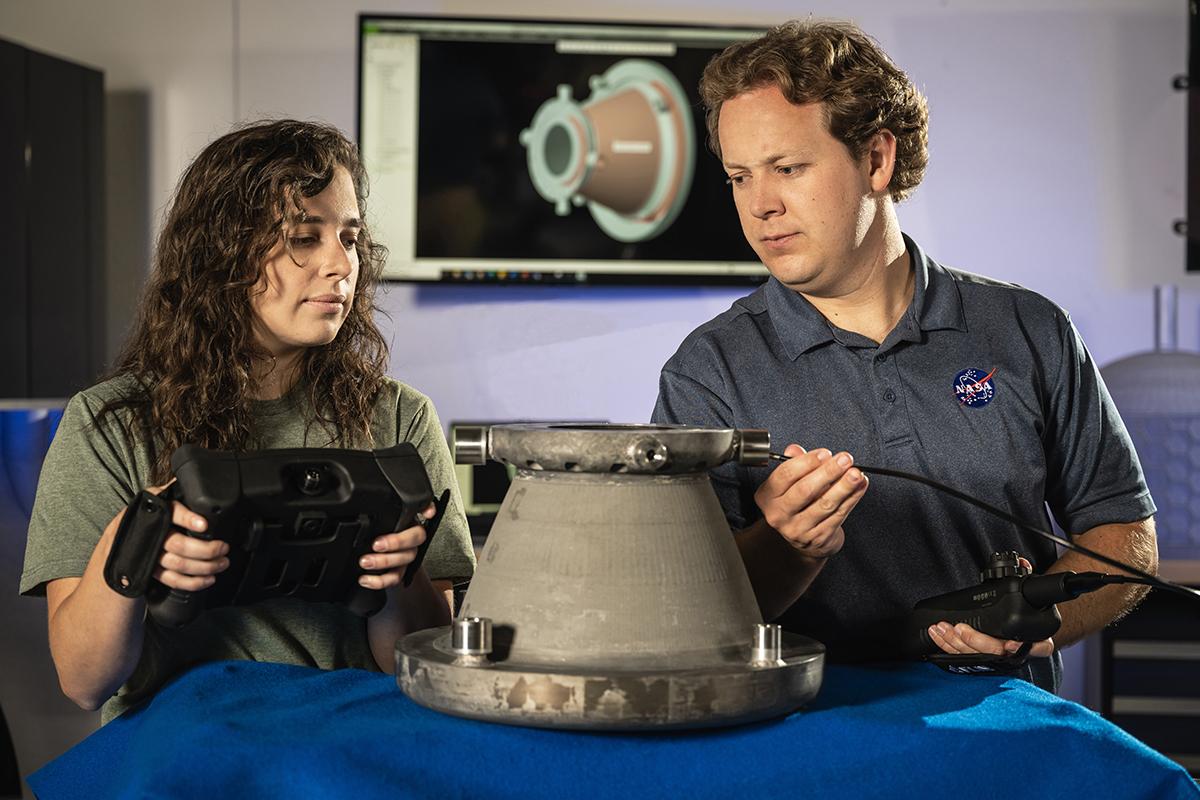

A portable electron beam gun for in situ curing was fabricated at Science Research Laboratory, Inc. before installation on the ATP head at NASA Marshall Space Flight Center.