A Genuine TEAM Player

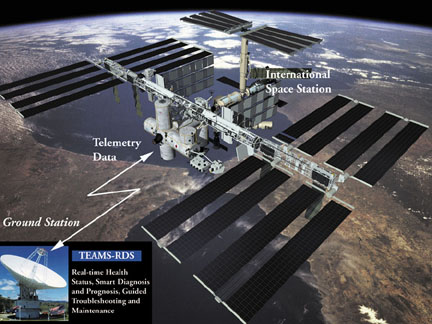

A new software system that quickly detects and isolates faults in complex, high-value systems such as the International Space Station is an extremely valuable product. Now, take that system, place it on a central computer and operate it remotely over the Internet, and you have a key enabling technology for the fast growing after-market service business that is using the Internet to generate new service revenue. What's more, the system covers all phases of a product's design, development, and support--a unique, comprehensive software system that could revolutionize the way diagnostics are designed, implemented, and deployed.

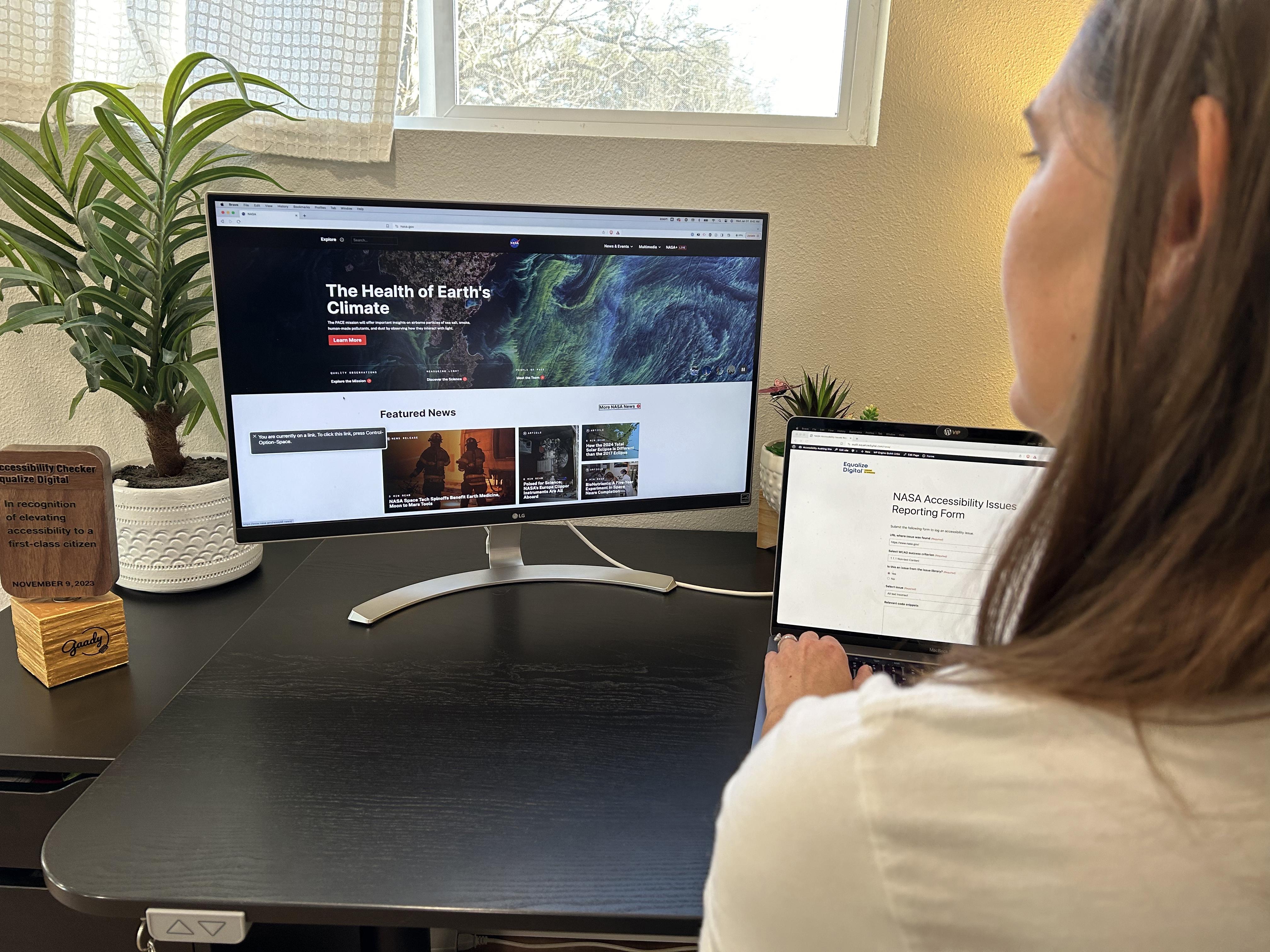

This software, with capabilities of multisignal modeling, diagnostic analysis, run-time diagnostic operations, and intelligent interactive reasoners, all in one package, sounds like a product of the future. But this is exactly what Qualtech Systems, Inc. (QSI), of Wethersfield, Connecticut, provided to the International Space Station crew. Through the Small Business Innovation Research (SBIR) program with NASA's Ames Research Center, QSI developed a complete multisignal modeling system that analyzes integrated systems during all stages of product design and maintenance. This software package, which is commercially available as the TEAMS (Testability Engineering and Maintenance System) tool set, can be used to reveal unanticipated system failures.

In the past, modeling systems could handle only one signal. QSI revolutionized the modeling process by taking the common model-based approach and developing it into a multisignal package, capable of providing a complete diagnostic solution for a variety of applications all based on a common model of the system design and diagnostic characteristics. The TEAMS software package is broken down into four companion tools: TEAMS-RT, TEAMATE, TEAMS-KB, and TEAMS-RDS.

TEAMS-RT identifies the good, the bad, and the suspect components in the system in real-time. It reports system health results from onboard tests, and detects and isolates failures within the system, allowing for rapid fault isolation. For example, TEAMS-RT could be sitting on a computer in Atlanta, Georgia, that is being fed data from 10 radar sites in the southeastern United States. Based on TEAMS models of the various radar systems and the sensor data arriving over the network, TEAMS-RT will automatically detect and isolate the failed or failing component. The diagnostic results can then be posted on a web page for the system operators, equipment manufacturers, and the on-site maintenance personnel.

The TEAMATE tool provides an intelligent, dynamic reasoner to efficiently drive the electronic maintenance procedure on a handheld or portable maintenance computer. With TEAMATE, the maintenance process is optimized for the time or cost, such that the root cause of the fault is isolated in the least amount of time or for the least cost. TEAMATE also logs each step of the maintenance process, the time required to complete each task, and the result of each maintenance step. TEAMATE can take over from where TEAMS-RT left off and intelligently guide the maintenance technician through the troubleshooting procedure, repair actions, and operational checkout.

TEAMS-KB serves as a model management and collection tool for various maintenance sites in addition to archiving the TEAMATE logged data. For instance, TEAMS-KB stores site profiles listing the support equipment, personnel skill levels, and capabilities available at various maintenance sites. TEAMATE then generates optimized maintenance procedures for a particular maintenance site with the available resources and capabilities. After maintenance is complete, TEAMATE logs every action/result/time interval back to TEAMS-KB for record keeping, tracking, trending, and data mining applications. It is also applied in model management, scheduled and unscheduled maintenance, and technical data management.

TEAMS-RDS (TEAMS-Remote Diagnostic Server), the newest member of the companion tools, has the ability to continuously assess a system and isolate any failure in that system or its components, in real time. RDS incorporates TEAMS-RT, TEAMATE, and TEAMS-KB in a large-scale server architecture capable of providing advanced diagnostic and maintenance functions over a network, such as the Internet, with a web browser user interface. RDS is a key enabling technology for emerging business-to-business e-commerce after market services with unparalleled capability for remote monitoring, diagnostics, expert guidance, and maintenance logging. QSI fully expects large manufacturers to be thrilled by the leading-edge telemaintenance functionality of this new software. TEAMS software is currently used by leading aerospace companies such as Sikorsky, Honeywell, BAE SYSTEMS, Boeing, and others. QSI sees potential commercial applications of the TEAMS software in industries such as plant machinery, automotive, building systems, utility systems, medical equipment, rail systems,appliances, information systems, and software testing.

The International Space Station uses Qualtech's TEAMS multisignal modeling technology to analyze and manage its complex integrated system from one central computer