Tweaking Analysis Tools to Give SAGE Advice

Subheadline

Sound predictive simulations can significantly cut development costs

While designing the telescope for a proposed NASA satellite, Quartus Engineering Incorporated spent extra time and money to intentionally build additional optical assemblies that would perform poorly under conditions like launch vibrations and the temperature fluctuations of space. The investment could pay off handsomely for both the company and NASA.

“The additional work we’re doing is not to validate the design itself,” explained Alexander Halterman, director of technical program development at the San Diego-based company. “It is to validate the tools and methods that are used to analyze the design, and therefore have higher confidence in future designs.”

The idea was to build assemblies that would be stressed and deform under harsh conditions and then ensure the company’s design analyses could correctly predict that behavior, fine-tuning those tools when their predictions were off. With confidence in proven analysis methods, engineers can more rapidly develop reliable systems that don’t need to be aggressively tested, adjusted, and rebuilt.

“The reason people don’t do this is because it costs a lot of money,” said Halterman. “But if we can cut out a design cycle that costs a few million dollars for multiple programs, this pays for itself in spades.”

The initial investment came from Small Business Innovation Research (SBIR) contracts from NASA’s Langley Research Center in Hampton, Virginia, funding the company to fine-tune its analyses as it designed the telescope for the proposed Stratospheric Aerosol and Gas Experiment (SAGE) IV satellite. The SAGE program observes the ozone layer and stratospheric aerosols — particles from volcanos and large fires that affect the chemistry and energy balance of the upper atmosphere. This is accomplished with a technique called solar occultation. Instruments in orbit observe sunrises and sunsets from space, extracting information by comparing sunlight passing through Earth’s atmosphere to sunlight above the atmosphere.

The Stratospheric Aerosol Measurement experiment demonstrated the technique in the early 1970s. SAGE instruments helped characterize a hole in the ozone layer in the 1980s, leading to a global ban on chlorofluorocarbons, and have been monitoring its recovery. SAGE IV would be smaller and cost significantly less than its predecessors, but it’s currently not funded for flight, said Robert Damadeo, who, as co-principal investigator for SAGE IV, oversaw Quartus’ SBIR work.

“It’s all about having a high-fidelity model that you can trust so when you build it, it works as you planned,” said Damadeo, noting that the capability could save NASA money on future projects. ”This is much more efficient when compared to the build, test, fail, and redesign cycle that has often been deployed in the past.”

Among Quartus’ commercial offerings are custom science payloads, and Halterman said the work could validate individual components that could be reconfigured for different purposes, from astronomical telescopes to Earth-imaging cameras and lidar sensors that build three-dimensional images. “One value this brings to the table is a high confidence in the building blocks of an architecture that can be repurposed for future instruments,” he said.

Halterman said these capabilities are especially interesting to entities like NASA and Quartus, which build a lot of unique systems, each requiring its own design, rather than higher-volume manufacturing. “We really just like working on cool projects,” he said. “We are drawn to the one-off instruments, because half of what’s interesting to us is learning about the science and how engineering can make that science a reality.”

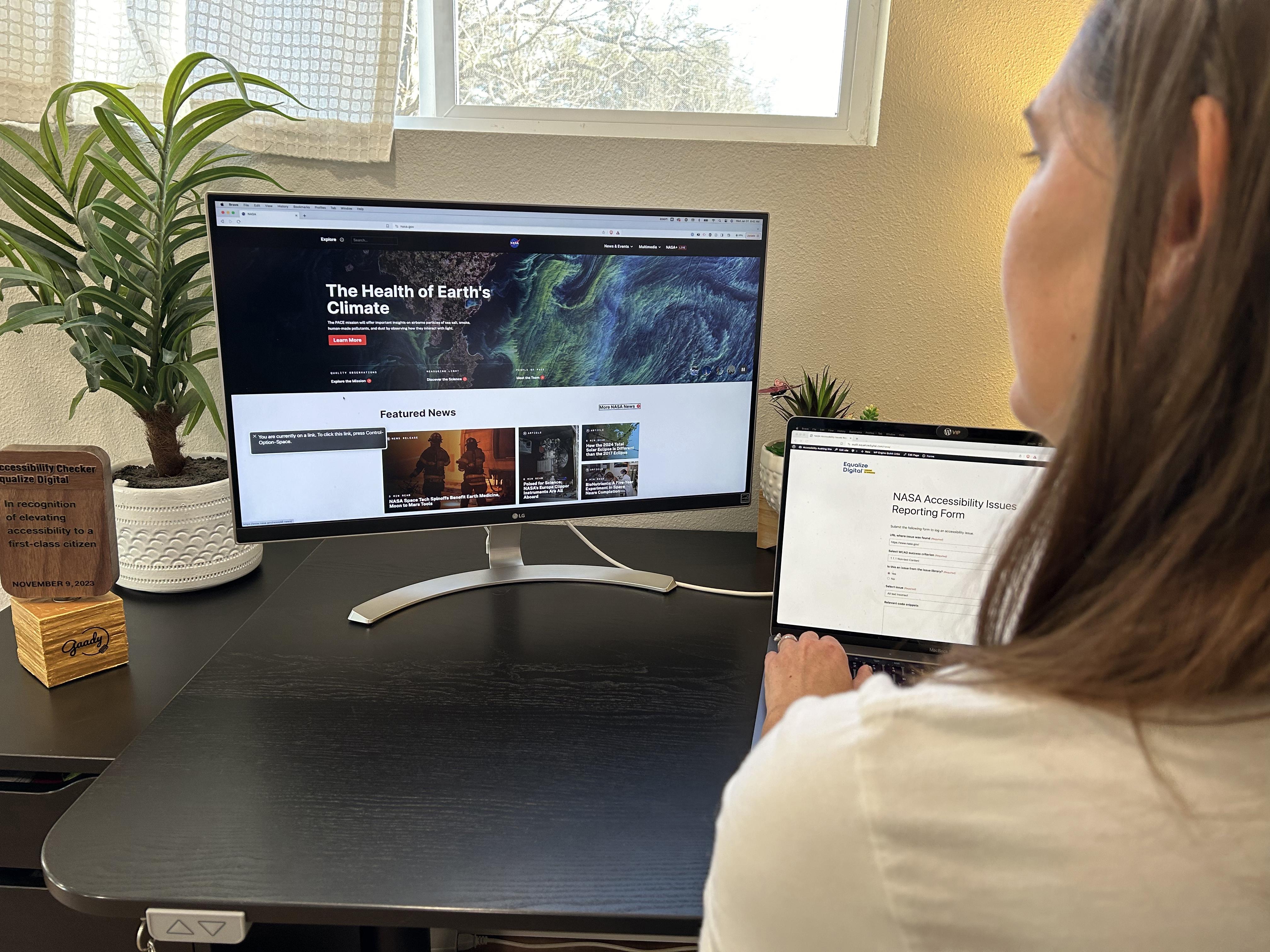

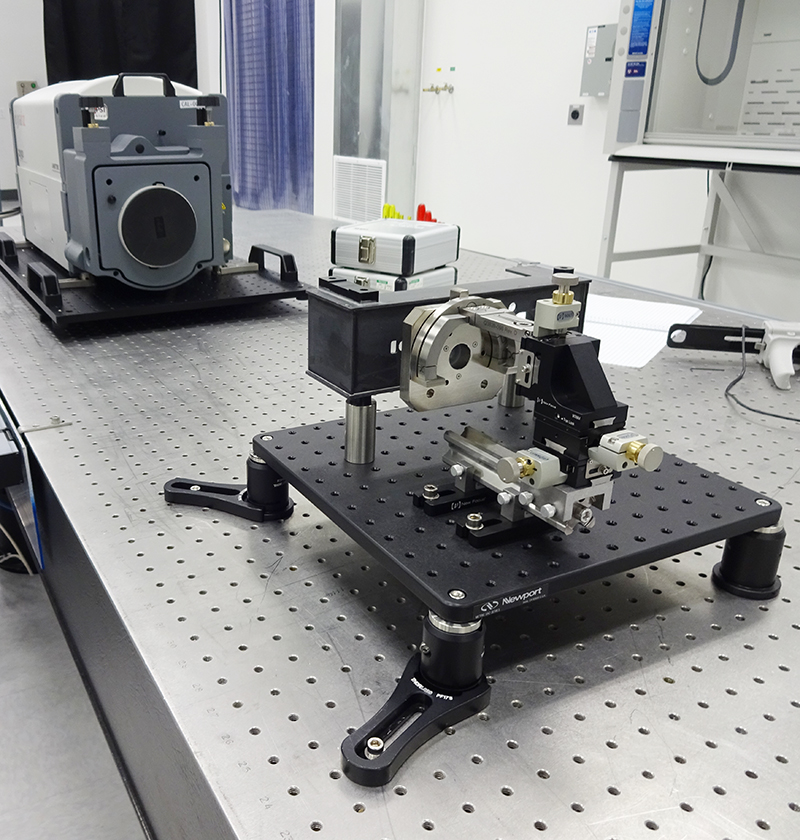

In this benchtop testing setup, Quartus Engineering carries out risk mitigation testing on the original Stratospheric Aerosol and Gas Experiment (SAGE) IV optical assembly demonstration unit. Credit: Quartus Engineering Incorporated

Robert Damadeo of Langley Research Center, co-principal investigator for the SAGE IV satellite, holds a model of the proposed little CubeSat’s bus beside a model of the far larger and more expensive SAGE III instrument, which is currently mounted outside the International Space Station. Credit: NASA