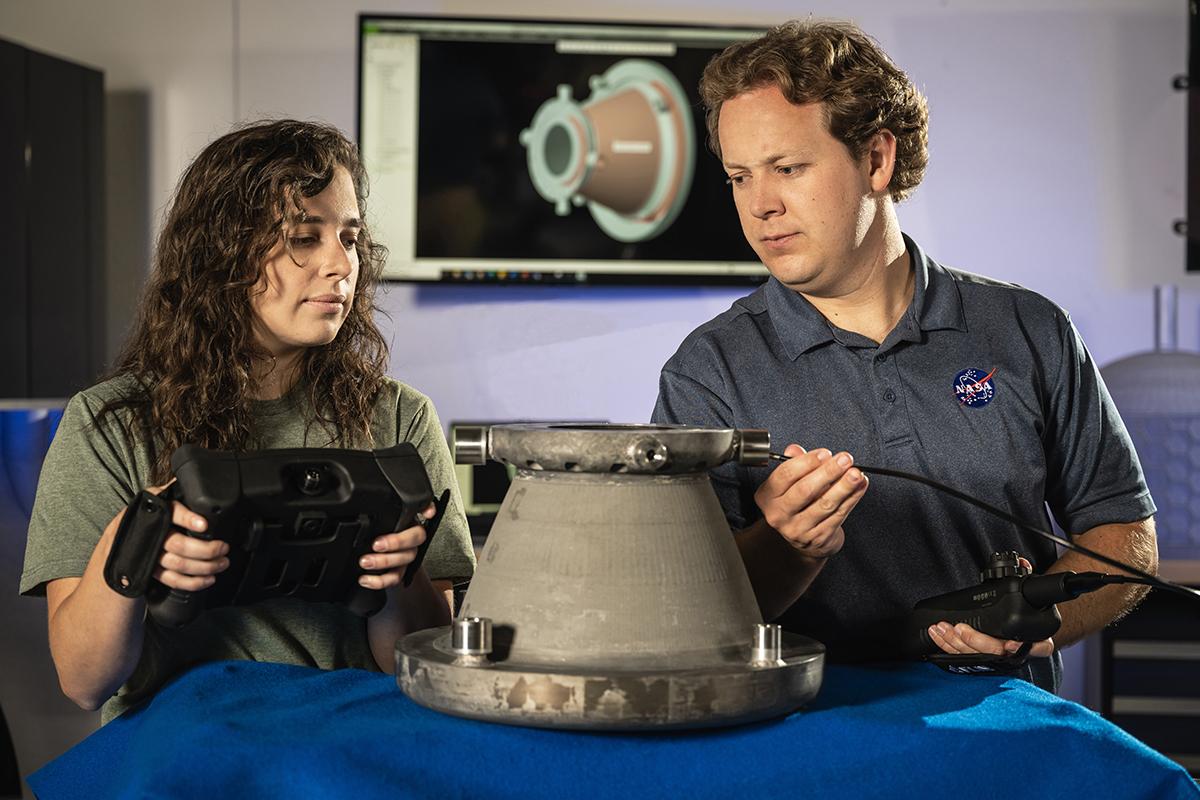

Portable Inspection

The harsh environment of space can be extremely unforgiving on satellite exteriors, thermal control surfaces, and power-providing solar cells. A hand-held device has been added to a spacewalking astronaut's toolkit, one that permits easy and reliable inspection of spacecraft surfaces. Such equipment is critical in determining maintenance schedules for thermal control surfaces of large and complex spacecraft, including the International Space Station. Work on the portable instrument for space has led to a variety of commercial products that are ideal for industrial applications.

AZ Technology, Inc., of Huntsville, Alabama, developed the Space Portable Spectro Reflectometer (SPSR) under NASA's Small Business Innovation Research (SBIR) program. In partnership with the Marshall Space Flight Center, the company designed the lightweight and portable instrument for use aboard the Space Shuttle. The company also created the Optical Properties Monitor experiment that was conducted on the exterior of Russia's Mir space station.

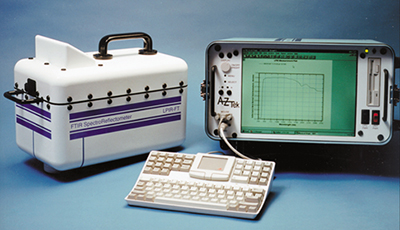

Drawing upon this NASA-sponsored work, AZ Technology has produced several commercial instruments, and has several more in development. One such device is the TESA 2000 (Total Emittance and Solar Absorptance), developed in partnership with NASA's Kennedy Space Center. The TESA 2000 portable inspection instrument is a powerful combination of two instruments, packaged for ease of use in the field or laboratory. As the name suggests, the apparatus measures both the near room temperature emittance and solar absorption of a material in order to fully characterize its radiative heat transfer properties. The product is designed to pack into two carrying cases that easily fit into the overhead bin of most airliners. Rugged and highly accurate, the unit is designed for years of field use and includes two rechargeable batteries and a battery charger.

Evaluations by NASA of the hardware included ground-processing tasks of the Shuttle and its payloads within the cargo bay. Specifically, the TESA 2000 determined the effectiveness of thermal insulation blankets and radiator surfaces. These blankets protect sensitive instruments from the ultra-heat and cold, as well as from damaging doses of space radiation. The tests suggested that surface inspection costs of a Space Shuttle could be cut in half, thanks to the equipment. Furthermore, it proved less bulky than older equipment utilized, thus the device was safer to use, particularly in tight, hard-to-access areas.

Commercial applications of the TESA 2000 include evaluating special coatings used by military on land, sea, and air vehicles. Coating manufacturers and testing laboratories could use the technology to measure surface reflectance properties of coating panels in environmental tests for weathering.

Additionally, TESA 2000 can evaluate the efficiency of solar cell or solar heating systems, and coatings and reflectance materials utilized in automotive glass can be assessed by manufacturers or testing laboratories.

AZ Technology has been able to develop a range of instruments through a vigorous technology transfer program with NASA. The company has also made space-stable, electrically conductive thermal control coatings resulting from NASA SBIR awards. Coupled with the company's expertise in materials testing and development of advanced spacecraft coating materials, the firm offers "one stop shopping" for spacecraft coating needs, as well as the ability to address many commercial needs.

AZ Technology, Inc.’s TESA 2000 is a portable inspection instrument, packaged for easy use in the field or laboratory.