A Particulate Matter

Even a microparticle of dust or fiber can foul up sensitive equipment being readied for a launch into space. Great care is a must in overseeing the cleanliness of conditions during ground processing of space payloads. A Florida company has found commercial uses for monitoring hardware designed to protect Space Shuttle payloads from mission-compromising contamination.

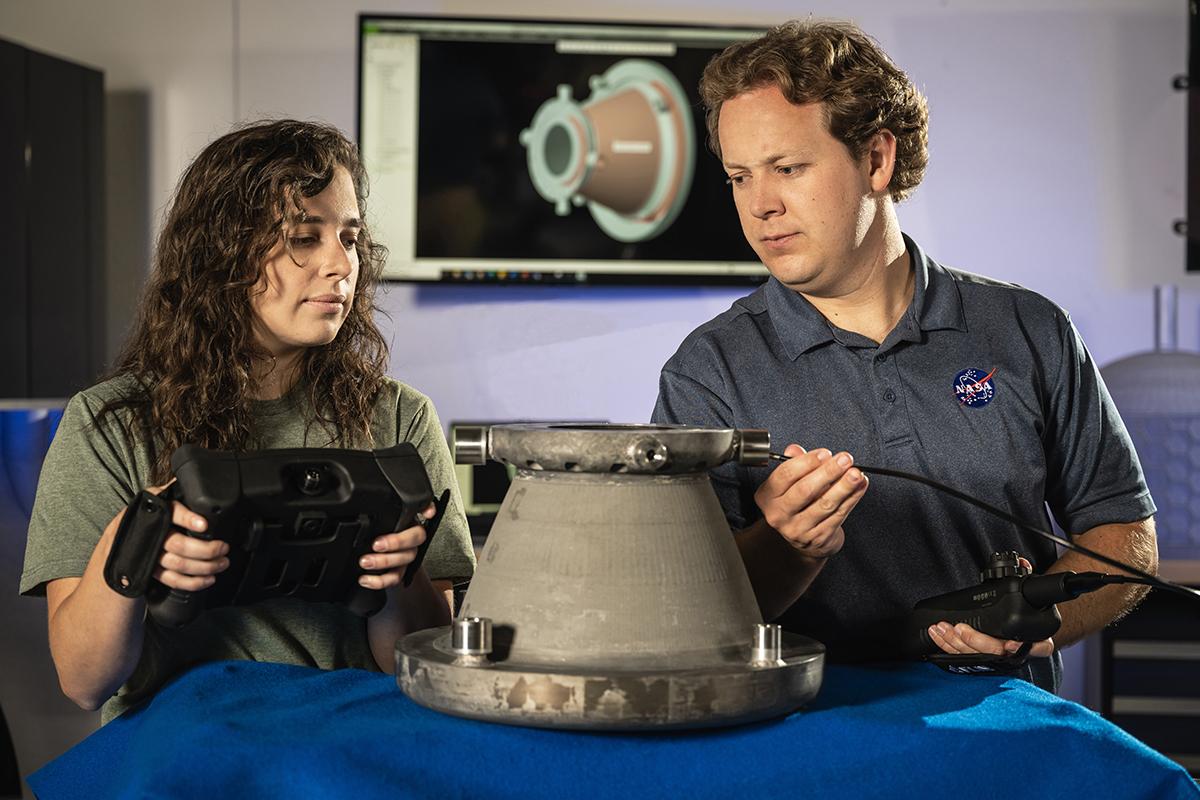

Technical Applications Unlimited (TAU), Inc., of Cape Canaveral, Florida, received a patent license for the Particle Fallout/Activity Sensor, now called the Real-Time Optical Fallout Monitor (OFM). TAU is a tenant of the Florida/NASA Business Incubation Center in Titusville. Kennedy Space Center's Technology Programs and Commercialization Office arranged this agreement. The firm has commercialized the sensor, developed at Kennedy to detect the accumulation of potentially damaging dust and fibers on delicate payload components.

TAU is marketing the OFM, highlighting the product's attributes for use in clean rooms, semiconductor manufacturing, pharmaceutical production, spacecraft processing, and food processing. Further applications include the monitoring of medical facilities, security systems, and air handling assessment.

Invented by NASA engineers, the sensor measures relative amounts of dust or other particles that have fallen onto a special wafer. Using an infrared light-emitting diode (LED), an optical assembly, and other microelectronics, fallout accumulations can be measured. The prototype sensor included a sensor module. The commercial OFM comes as a single unit. TAU improvements have also enhanced the instrument's sensitivity.

The OFM is portable, compact, and weighs little more than three pounds. The unit can detect single particles as tiny as 10 microns. Fallout accumulation measurements can be displayed on the OFM's front panel and/or downloaded for remote monitoring analysis.

The role of the Florida/NASA Business Incubation Center, established in 1996, is to assist entrepreneurs and small businesses by offering office space at a reduced cost and providing technical assistance to tenants. The center is located in Titusville, situated on the campus of Brevard Community College.

A computer chip maker purchased OFM units to assess the ability of the hardware to detect sources of contamination that can lead to defective chips coming off the assembly line. An aerospace company purchased a unit for use during integration of its spacecraft, the first of which was a Titan IV rocket at the end of 1998. A bio-pharmaceutical manufacturer is evaluating the unit too, for inclusion in their manufacturing process to spot environmental intrusions that render their products unusable. A major nuclear laboratory is considering the OFM as a possible aid to detect environmental fallout in various experimental nuclear processes. Also, a major U.S. photographic firm is eyeing the OFM as an aid to assess cleanliness in film manufacturing.

TAU president John Horan, Jr., explains, "NASA has made it possible for TAU to get off the ground with a high technology product that would have taken years and many more resources than a typical small business start-up company can make available. We feel like TAU will be able to compete with the instrumentation industry leaders as a result of this boost from NASA."

"We have several units now successfully sold to, and in current use by, high technology companies who have environmental monitoring needs that are consistent with the instrument's capabilities. Those companies range from spacecraft manufacturers to integrated circuit manufacturers," Horan adds.

Technical Applications Unlimited, Inc.'s Real-Time Optical Fallout Monitor is designed for use in many areas of industry.