Sensor Validation Software

Call it "reasoning with uncertainty." That is the raison d'etre of Expert Microsystems, Inc. of Orangevale, California.

The company developed SureSense™, real-time sensor data validation software. The work was a direct result of a Small Business Innovation

Research (SBIR) contract with Lewis Research Center. This ultra-reliable control and sensing system product was produced and distributed through a partnership in 1994 between Expert Microsystems and Intelligent Software Associates, Inc. (ISAI).

SureSense was created in response to a NASA need for verifying the reliability of sensor input that operates advanced automation and control systems.

The SureSense software had an immediate assignment: improve safety and reliability of Space Shuttle Main Engine (SSME) operations. Along with its unprecedented number of successful flights, Space Shuttle history also illustrates the potential value of sensor validation. The program has suffered test aborts, launch delays and postponements as a result of sensor failures. Dangerous conditions may result when the sensors used to prevent catastrophic system malfunction fail themselves.

SureSense was designed to detect failures in sensors that must function in a trustworthy manner. Erroneous engine shutdowns due to sensor failures are costly, with any test abort or launch delay forcing an expensive and time-consuming anomaly investigation.

In one dramatic instance, sensor failure caused the premature in-flight shut down of an SSME roaring toward orbit. Space Shuttle mission 51-F in July 1985 had the number one SSME shut down early. Luckily, the Shuttle was over five minutes into its ascent and was capable of an "abort to orbit." On the second engine, sensors also indicated that shutdown was

necessary. A mission operations engineer noticed an incongruency in the sensor readouts and advised against it.

Expert Microsystems's SureSense real-time sensor validation software reduces the workload, schedule and uncertainty associated with sensor failure identification and recovery. Furthermore, data integrity also improves safety, dependability and economics for any mission critical aerospace or industrial control application.

Sensor validation is advantageous for several reasons. Among them:

- averts safety system false alarms that leads to unwarranted shutdown or maintenance,

- lengthens hardware life and assures mission success,

- provides reliable "red-line" safety protection for personnel and equipment, and

- strengthens system automation by ensuring that automated checkout and diagnostic systems "reason" with valid data.

The NASA work led to recognizing the wide-spread commercial potential of sensor data validation software, says Randy Bickford, President of Expert Microsystems. The company has structured the software to enable application to virtually any process control environment, such as computer integrated manufacturing, power plants, and hazardous gas sensing and control systems.

It is estimated that the nationwide market for special purpose industrial controls is in the billions of dollars, indicating the size and diversity of the process controls market.

SureSense is a trademark of Expert Microsystems, Inc.

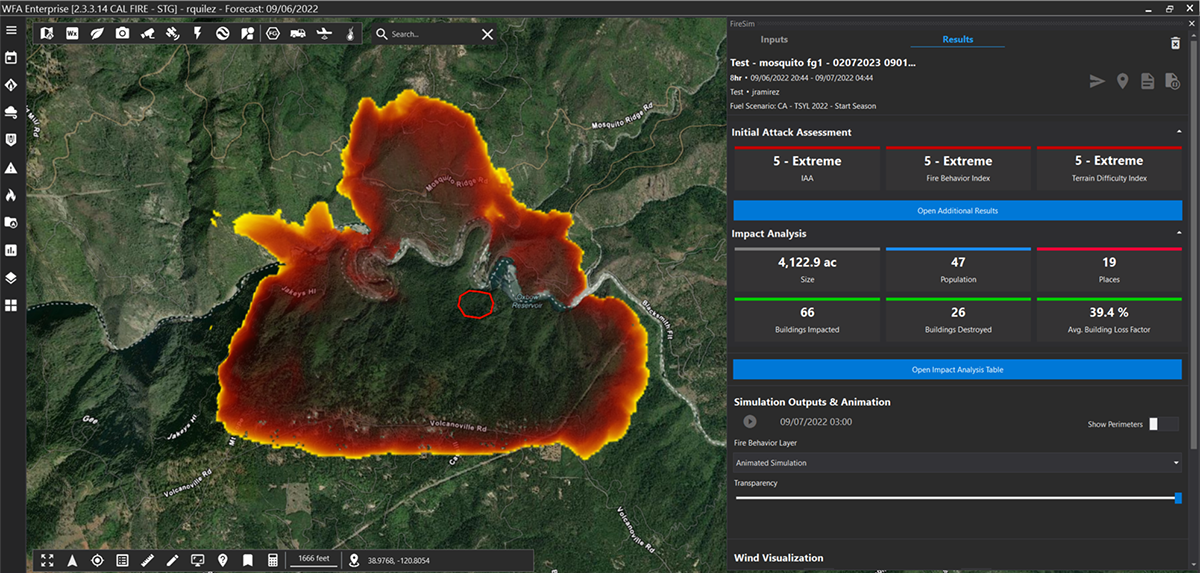

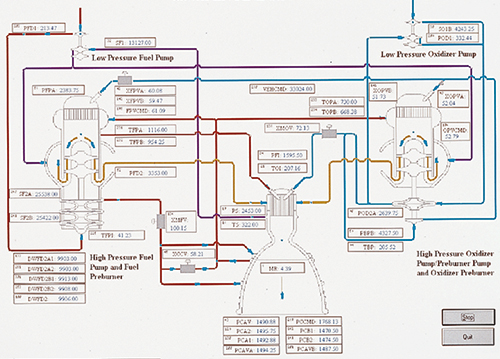

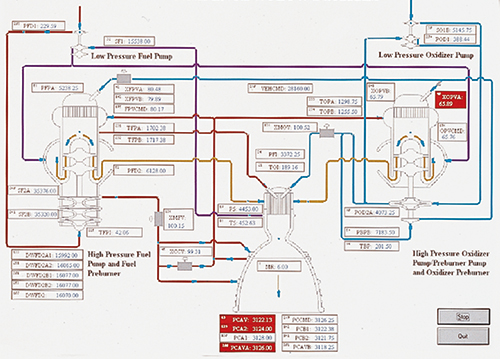

Expert Microsystems, Inc.'s validation software was developed for verifying sensor operations in Space Shuttle Main Engines (SSMEs). The user interface screen shows normal operation of the SSME during testing at Marshall Space Flight Center's avionics simulation facility.

In real-time, SureSense software can depict failure of several mission critical sensors on the Space Shuttle Main Engine and highlight the sensor value display in red.