Ultrasonic Maintenance

Originally published in 1991

Body

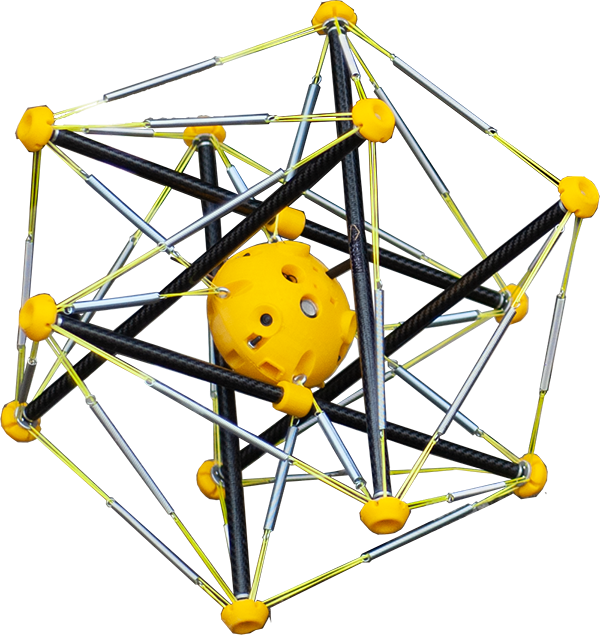

The Ultraprobe 2000, manufactured by UE Systems, Inc., Elmsford, NY, is a hand-held ultrasonic system that detects indications of bearing failure by analyzing changes in amplitude. It employs the technology of a prototype ultrasonic bearing-failure monitoring system developed by Mechanical Technology, Inc., Latham, New York and Marshall Space Flight Center (which was based on research into Skylab's gyroscope bearings). Bearings on the verge of failure send ultrasonic signals indicating their deterioration; the Ultraprobe changes these to audible signals. The operator hears the signals and gages their intensity with a meter in the unit.

Full article: http://hdl.handle.net/hdl:2060/20020086312

Abstract

The Ultraprobe 2000, manufactured by UE Systems, Inc., Elmsford, NY, is a hand-held ultrasonic system that detects indications of bearing failure by analyzing changes in amplitude. It employs the technology of a prototype ultrasonic bearing-failure monitoring system developed by Mechanical Technology, Inc., Latham, New York and Marshall Space Flight Center (which was based on research into Skylab's gyroscope bearings). Bearings on the verge of failure send ultrasonic signals indicating their deterioration; the Ultraprobe changes these to audible signals. The operator hears the signals and gages their intensity with a meter in the unit.

Ultrasonic Maintenance

Ultrasonic Maintenance