Zero-Leak Valve Holds Tight in Demanding Environments

NASA Technology

There’s no safe way to set anything substantial on fire on the space station to observe how spreading flames act in zero gravity, to test a fire extinguisher, or to see if protective gear will perform as designed. So NASA must use everything already learned in and about space to prepare for a worst-case scenario, including constantly evaluating fire protection tools and technology. One such review revealed an opportunity for improvement.

Some fire extinguishers in NASA space vehicles and the U.S. modules of the space station contain carbon dioxide (CO2) and halon, chemicals that can pose risks for humans and an enclosed environment, respectively. On the space station in particular, this raised a serious concern because emergency breathing equipment doesn’t filter CO2.

This prompted the Agency to develop a safer option. The new hand-held fire suppression system needed to be lightweight, discharge rapidly, and work on a variety of fires (electrical, composite materials, chemicals, and others). It also had to contain liquids or gases readily available on missions to enable a refill after a discharge. A fine-water-mist portable fire extinguisher made the most sense: it wouldn’t cause damage to structures or require special cleanup procedures and would meet the other criteria.

The Colorado School of Mines performed early NASA-funded research on the rudiments of water mist technology, culminating in a spaceflight experiment flown aboard space shuttle Columbia. Building on those initial results, Glenn Research Center and ADA Technologies developed a novel design that would work in microgravity. The extinguisher would discharge from any orientation because it didn’t rely on gravity to produce the unique thermal properties of micro-atomized water droplets.

The metal tank accommodated 6 pounds of water and 1.2 pounds of nitrogen gas. Held under pressure in separate bladders, thewouldn’t release until the extinguisher handle was squeezed, triggering the flow. That opened two cartridge valves and allowed the nitrogen and water to mix before discharging through the nozzle. The effervescent water would put out flames in an open cabin, and a special wand extension attached to the nozzle would reach fires behind an instrument rack or wall.

Technology Transfer

The success of the new extinguisher hinged on one part—a zero-leak valve. Doering Company LLC, then a small, family-owned company based in Clear Lake, Minnesota, provided that critical part. The company specializes in the precision design and quality construction of valves to meet the most demanding performance requirements. Zero-leak valves were already part of Doering’s catalog, but Marty Dombroske, vice president, says that level of performance is not the industry standard.

“Almost every valve has a leak rate associated with it, and that leak rate is going to decrease your level of pressure,” he explains.

Doering was able to modify an existing zero-leak valve to meet the exacting requirements for space.

A number of Small Business Innovation Research (SBIR) contracts from Glenn funded ADA’s development of the fine-water-mist extinguisher over the course of 10 years. During that time, specialists like Doering were contracted to create specialized components such as the zero-leak valve. The project team established fire test standards for microgravity environments and built a technology suitable for use in space and on Earth.

Russ Doering, retired president of Doering, says the process of customizing and testing the company’s zero-leak, air-piloted poppet valve challenged everyone in the company to take their already high standards to a new level.

“Each valve was serialized and had its own documentation,” explains Doering. “All that was new ground, so it gave us that capability going forward. We later had other projects where we were able to do trace-gas testing and document it.”

A point of pride for Doering is the fact that the final product exceeded the project’s requirements.

Benefits

All nine new water fire extinguishers built to replace the original CO2 fire suppression devices arrived on the space station by 2016. And the class of zero-leak valve orbiting Earth is now improving the performance of systems in numerous industries with equally demanding requirements.

From industrial to military applications, the primary advantages of this precision hardware over standard valves are performance and safety. When leaks can result in unacceptable risks or negatively affect outcomes, zero-leak is essential.

One client uses the pneumatic-piloted poppet cartridge valve in a grease dispenser built for industrial applications such as automotive assembly. During vehicle production, numerous locations require an application of grease. The ability to squirt the liquid where it’s needed might seem simple enough, but oil viscosity changes with the temperature. Whether the grease is cold and thick or warm and runny, the valve in the dispenser that controls the flow must close completely. Otherwise, that slippery substance could end up on the assembly line floor, posing a serious risk to workers.

Hydraulic equipment depends on effective valve operation to maintain the right level of liquid and pressure in a system. This is one of the applications where valve leakage is common, even expected, because of how hydraulics function, according to Dombroske. A very high pressure or force combined with a small amount of fluid in a contained space (such as a piston) enables a machine to move extremely heavy objects. For example, a bulldozer employs hydraulics to shift tons of soil or rocks. Such a powerful force can easily cause leaks. However, such a leak can endanger human life.

“A manufacturing company had a problem with the equipment that holds large rolls of papers for printing presses,” says Dombroske. “They had a valve that was leaking. The hydraulics weren’t able to keep that paper that weighs multiple tons in position overnight. A worker could be crushed if it failed completely.”

The company installed Doering’s hydraulic piloted poppet cartridge valve to address the immediate safety need. At the same time, they sent more of the valves to their facility in Italy for extensive testing. Now these valves are the only approved hardware for the equipment.

Another high-risk application is the Growler A/M32K-10 munitions trailer. This military vehicle transports up to 15,000 pounds of munitions and carries a safety requirement for the trailer’s brakes to hold for 24 hours before deploying an emergency parking brake. The first valve failed, allowing the trailer to move. The Doering valve never failed and is installed in more than 450 Growler trailers.

Russ Doering credits the NASA project with making it possible to introduce the zero-leak valve to new markets. In addition to NASA “helping us in our weak areas,” Doering says the staff “came out with a better knowledge of what our capabilities were.”

“It was interesting to work with NASA,” he says. “They were willing to spend the time to fully communicate and to look at the design objectively. That cooperation was really great.”

While the company expands its reach into new markets such as mobile and industrial hydraulic, the zero-leak valve is getting ready for another trip into space. NASA is developing the next-generation fine-water-mist fire extinguisher using the same Doering valve. This new fire extinguisher is for the Orion spacecraft.

A set of nine fine-water-mist fire extinguishers were built to replace the carbon dioxide extinguishers that were incompatible with astronaut emergency breathing equipment. They were designed to fit in the existing storage lockers, with the last one arriving on the space station in 2016. Image courtesy of Angel Abbud-Madrid, Colorado School of Mines

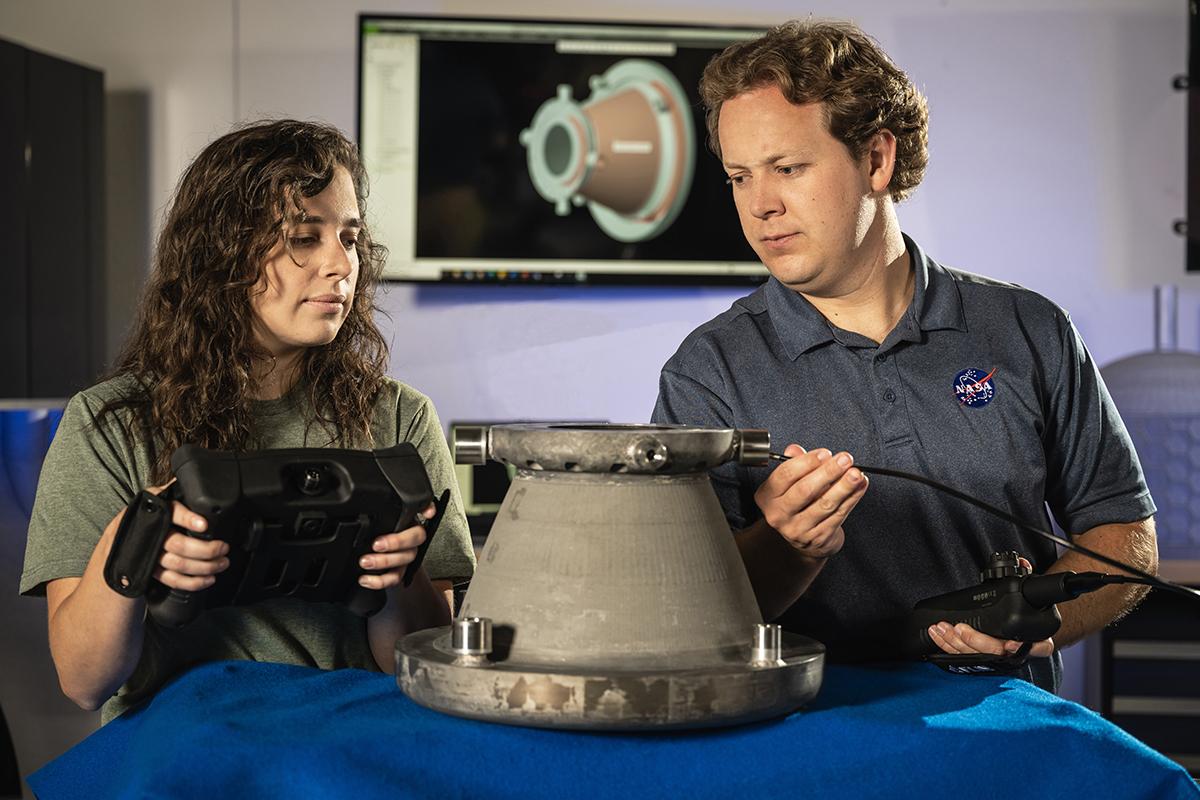

ADA Technologies received several NASA SBIR and STTR contracts that enabled the development of a fine-water-mist portable fire extinguisher intended for use aboard the ISS. The device required a no-leak valve, which Doering Company LLC built and now sells for industrial, military, and other applications. Image courtesy of Thomas Cooper, Lightbox Images