Sound Modeling Simplifies Vehicle Noise Management

NASA Technology

Exposure to a noise level of 105 decibels causes hearing damage after an hour or less. Concertgoers in the front row at a rock show can expect sustained noise of about 120 decibels. The sound of a lightning strike, up close, is 165 to 180 decibels. This is around the level that NASA acoustical engineers have to worry about, as rocket components during liftoff are exposed to sound levels up to about 170 decibels a blast so intense it could destroy the rocket or damage payloads if not properly managed.

Virtually no one but rocket scientists works to manage sustained acoustic levels of this magnitude.

While NASA has a clear interest in noise management, so do many commercial industries, such as car manufacturers and airplane builders, albeit at lower noise levels, and NASA often works with the aeronautics industry to develop efficient methods of noise management. An important part of this work is using computer software to predict and understand noise and vibrations.

Acoustical engineers generally use different analysis methods to predict noise and vibrations at different frequencies. One technique that simplifies modeling high-frequency noise and vibration was pioneered with NASA funding and is now in use by auto manufacturers and even found an application in locating hard-to-find leaks in the International Space Station (ISS).

To predict sound behavior at frequencies up to a few hundred hertz, engineers use what is called finite element analysis (FEA), explains Randolph Cabell, assistant head of the Structural Acoustics Branch at Langley Research Center. The method relies on a computer model of the structure in question, represented as a set of elements interconnected at nodes and assigned various properties, such as thickness, density, modulus of elasticity, and others.

Applying an FEA model, researchers can predict how relatively low-frequency sound or vibrations will travel in and around the structure, Cabell says. “If you want to make it quiet, you want to know how energy is moving around a structure so you know how to stop it.”

However, an FEA model requires a certain number of elements per wavelength, and as wavelengths get smaller at higher frequencies, the elements become so tiny and so numerous that conventional FEA becomes cumbersome, especially for a structure the size of an airplane, he says. Minute details such as fastener locations, the tightness of rivets or the number of coats of paint become significant for accurate sound and vibration prediction.

This is why acoustical engineers use a different method called statistical energy analysis (SEA) to predict high-frequency noise and vibrations. SEA uses a simpler model than FEA, with the vehicle's structure and interior cabin divided into a few large regions, but still provides practical information for understanding and reducing noise and vibrations. However, Cabell says, the accuracy of the SEA model depends on the user intelligently dividing the structure into analysis regions. More importantly, while aircraft designers often work with FEA, they don’t use SEA, so it is up to the acoustical engineer to modify the SEA model each time the designers change the airplane design. This increases the workload and introduces possibilities for error in the acoustical analysis.

Despite this downside to SEA, no other method existed for predicting high-frequency sound behavior.

Technology Transfer

In 2004 and 2005, NASA awarded Phase I and II Small Business Innovation Research (SBIR) contracts to Ann Arbor, Michigan-based Comet Technology Corporation (CTC), which was developing a way to eliminate the need to build two models. The company’s chief technology officer, Ravi Raveendra, had proposed software that would enable energy finite element analysis—a method that would provide a unified framework for analysis of both low- and high-frequency noise.

The company had just split from now-defunct Automated Analysis Corporation, where it had been developing vibroacoustics software since 1993.

“We thought it would be good if we could extend what we’d done for low-frequency to develop a method for high-frequency,” Raveendra says. “Most of the time, the customer’s not interested in the low-frequency area alone.”

The result of that NASA funding—Comet EnFlow software—went on the market in the late 2000s and has succeeded in eliminating the need for two models.

“EnFlow lets you do high-frequency analysis on the grid you used for low-frequency analysis,” Cabell says, explaining that the software takes the original model used for low-frequency FEA and creates an accurate but coarser model for predicting high-frequency sound and vibration. “It can read the node locations and parts that make up each element in that model so you don’t have to recreate it, and it will run the high-frequency analysis from that FEA model.”

Benefits

Raveendra markets the software to automobile and aircraft manufacturers, some of whom have purchased it, and he says CTC has received interest from the consumer product industry and ship builders as well. Using this NASA-funded technology, these companies are able to achieve the cost savings and quality improvement that come with early-stage noise modeling while saving the time and money it takes to create new computer models for use in the SEA method.

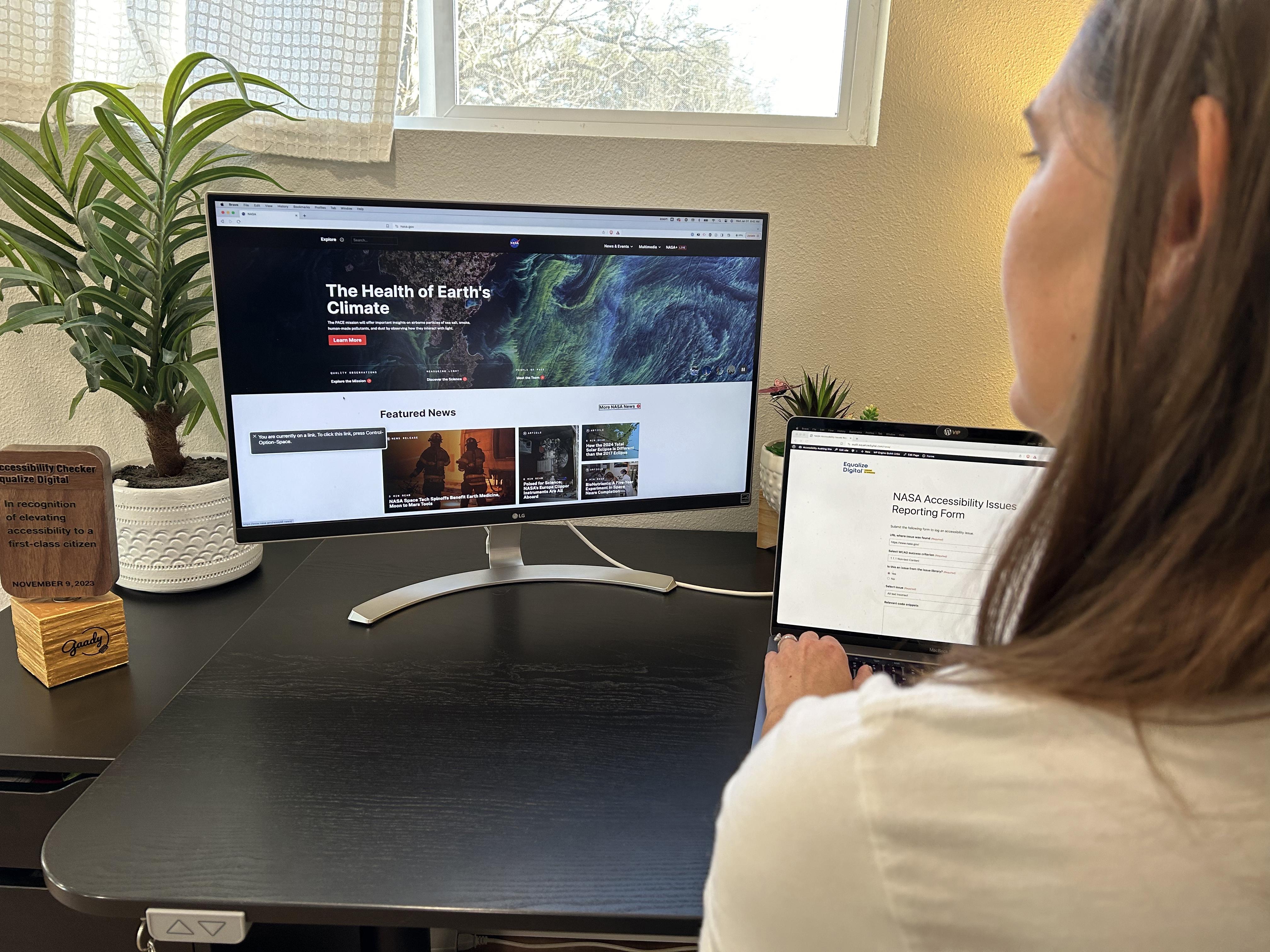

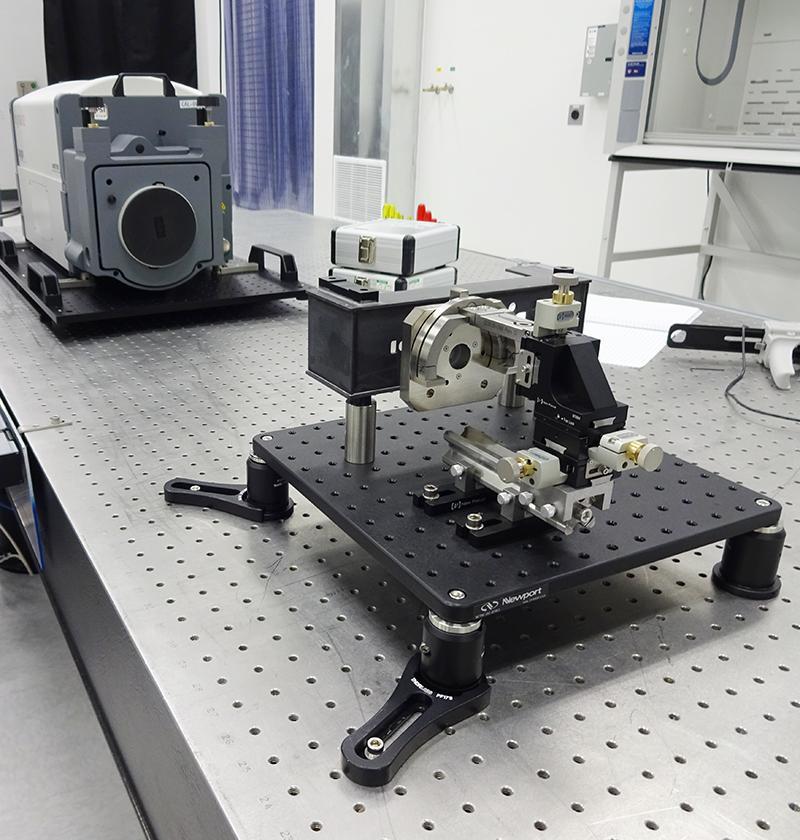

In addition to being evaluated by NASA’s Structural Acoustics Branch, EnFlow also found an unexpected use in the Nondestructive Evaluation Sciences (NDES) Branch, also at Langley.

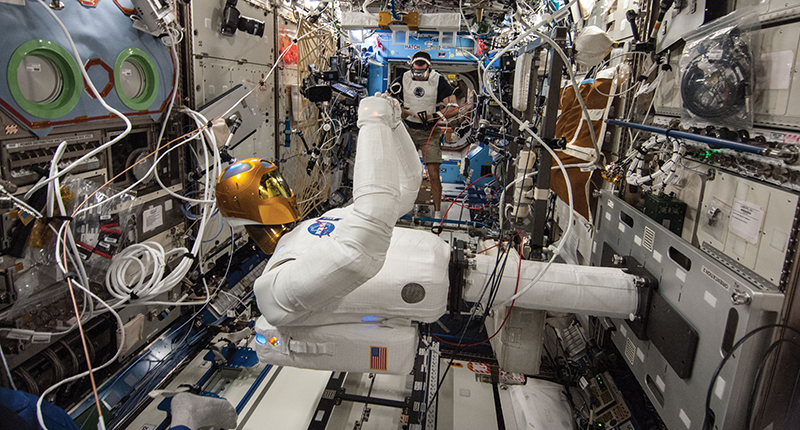

About 10 years ago, NASA’s Structures and Mechanisms systems manager for the ISS approached Eric Madaras, senior physicist with the NDES Branch, looking for ideas for a way to rapidly detect any leak in the space station’s pressure walls. These can be caused by micrometeoroids or satellite debris. Astronauts on the ISS have a handheld ultrasonic leak detector, but it can only find an exposed leak. This limitation is problematic in a structure whose walls are often covered with stowage and equipment, Madaras says.

“Being able to have someone tell them, ‘it’s behind a rack on the portside, four racks down’—that’s a big help,” he says.

He dropped in on Cabell, who often works with the same sort of technologies Madaras uses, and learned of EnFlow, which was still in development. Since the software was being designed to analyze a structure’s vibro-acoustic field and predict energy flow, he thought it could be coupled with sensors to pinpoint the sound of a leak. And because it works with high frequencies, it could calculate for a leak in the ultrasonic range, where there is much less background noise. Most noise on the ISS is in the acoustic range, while a leak is “pretty efficient at producing sound in the ultrasonic range,” Madaras says.

He bought the software package in 2009, had the pressure walls of the US lab module outfitted with sensors and found that he was able to use Enflow to pinpoint direct, ultrasonic vibrations from equipment in the module. As a result, he says, “Our recommendation to senior management will be that they should outfit all permanent modules on the ISS with this technology.”

Raveendra said he hadn’t known his product was capable of leak detection until Madaras approached him. “We never thought about it,” he says, adding that he is in the process of making some modifications to EnFlow to market it not only for sound behavior prediction but also for ultrasonic leak detection, which is an area many companies have an interest in.

He adds that he probably couldn’t credibly repurpose the software without NASA’s experimentation to prove its effectiveness in a totally different function. “This is an application we’ll expand,” he says. “We needed that experimental work to validate what is possible with this software.”

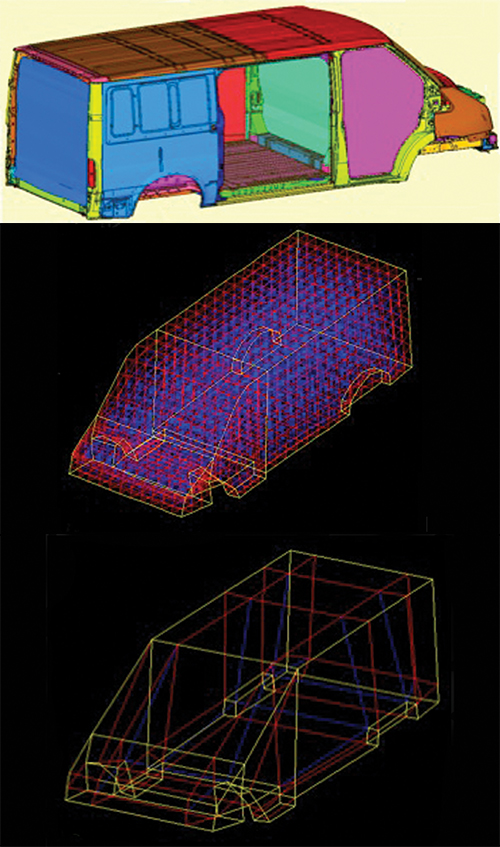

Software for sound modeling using traditional finite element analysis (FEA) relies on a highly detailed computer model of the structure being analyzed, like the one at top. To predict the behavior of higher-frequency sound using statistical energy analysis, engineers have had to create another, coarser computer model. Comet EnFlow software eliminates that step by building less refined models, such as the lower two, based on the FEA model.

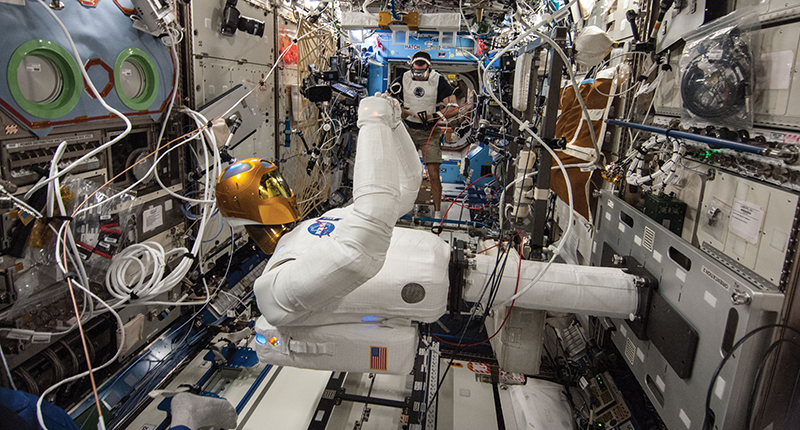

NASA's Robonaut works in the US Destiny Laboratory module of the International Space Station (ISS). Finding a pressure-wall leak with a handheld leak detector is a challenge in the ISS, where the interior walls are covered in storage and equipment. The agency found an unexpected use for Comet EnFlow software in detecting leaks with a series of sound sensors on the walls of the Destiny module.