Modified Fittings Enhance Industrial Safety

NASA Technology

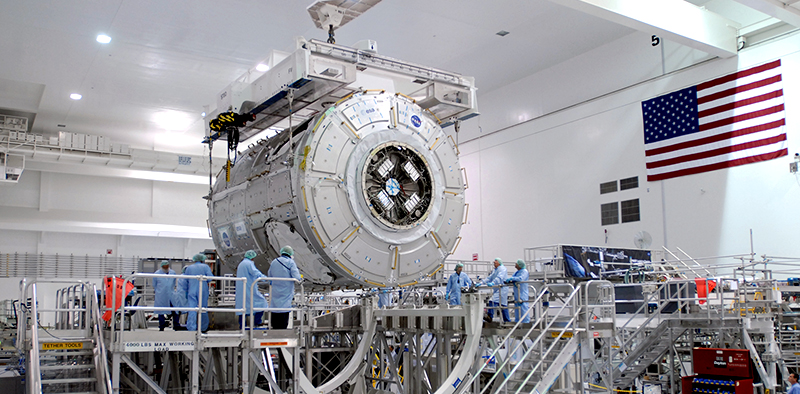

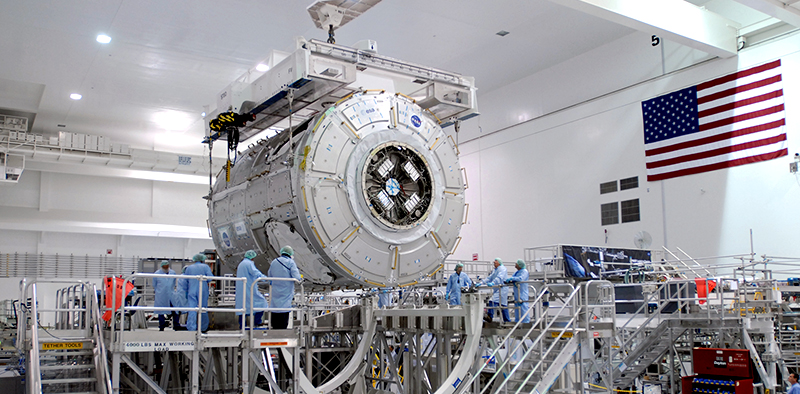

Kennedy Space Center is not onlyto one of the largest buildings in the world—the massive Vehicle Assembly Building—it also hosts a number of one-of-a-kind facilities. The more than 30-mile-long campus has witnessed every launch from the Space Shuttle Launch Pad, as well as many homecomings at the Shuttle Landing Facility. Just as important, the Space Station Processing Facility (SSPF) has seen each element of the International Space Station (ISS) that passes through Kennedy before it goes into orbit.

The SSPF is where ISS components are checked, tested, and adjusted before being packed into the space shuttle for transport. In an environment like the SSPF—spanning 457,000 square feet of processing areas, operational control rooms, laboratories, logistics areas, and office space—large workstands and equipment used to support the processing of ISS components need to be moved around the facility. One of the devices employed for this task is an air pallet. An air pallet moves on cushions of air instead of wheels. Compressed air inflates the cushions underneath the pallet and is then expelled through exhaust holes. This forms a thin film of air between the cushions and the floor, lifting the platform off the floor and making it easy to move the heavy workstands, equipment, and ISS components.

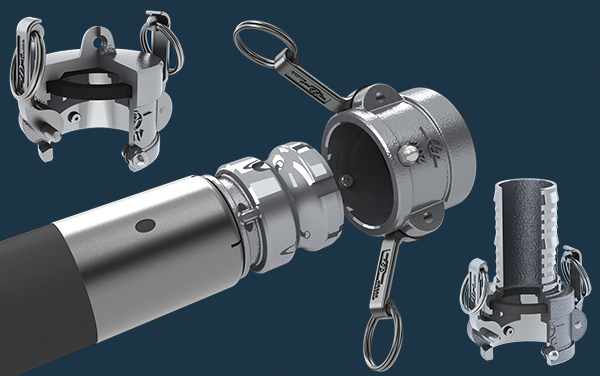

Concerned with the safety of the connections on the pressurized air hoses used for the air pallets, engineers at Kennedy modified an existing commercial cam and groove fitting to control the air supply hose in the event of an accidental release of a pressurized hose. This modification prevented the hose from detaching and, propelled by compressed air, striking workers or equipment.

Partnership

Years after NASA modified the coupling halves, an engineer at an Enid, Oklahoma-based business, PT Coupling Company, was looking for a solution for one of the company’s customers working in Alaska’s North Slope. The customer had some incidents on a pipeline where fittings under pressure were disconnected and resulted in injuries to the workers.

To address the problem, the company developed some prototypes, but nothing worked well, says Kyle Eckhardt, the engineer at PT Coupling. “I was trying to come up with a solution when I came across the NASA fitting description while doing some research online. It was simple, practical, and it really worked,” he says.

Eckhardt contacted Pasquale Ferrari, a technology transfer agent at Kennedy, and then signed an agreement to transfer the hardware modification. “It’s something that NASA made that nobody else was making,” says Ferrari. “Part of NASA’s mission is to move technology, and that is what we did.”

Benefits

PT Coupling made additional changes to the NASA-modified fittings. These included removing a catch slot on the front of the adapter, developing different hardware sizes (2- and 3-inch sizes), and using new materials. “NASA’s fitting was aerospace grade and very expensive. We came up with materials that had the same properties but were more common,” says Eckhardt. By 2011, PT Coupling started offering a promising new product for the petroleum and chemical industries called PT Pressure Safe.

As a manufacturer and distributor of industrial fittings for liquid and dry material transfer applications, PT Coupling makes cam and groove couplings. Such fittings are made up of two parts: a male (adapter/plug) and female (coupler/socket) that work together. The male adapter and female coupler are easily connected to make contact with the gasket, and then two arms on the coupler are depressed simultaneously to produce a seal. To release the seal, the arms are lifted. A main benefit of the fittings is quick connection and disconnection without using hand tools or threaded connections.

“As quick release fittings, they are designed for when hoses are constantly changed. Threaded fittings take more time to tighten and loosen. With cam and groove, you simply actuate the two arms to connect or disconnect the fitting,” says Eckhardt.

While these cam and groove fittings are quick and easy to connect and disconnect, they can be dangerous if disconnected under pressure. The new PT Pressure Safe fittings, based on the NASA-modified coupling halves, solve this problem by capturing the energy and releasing it in a controlled and safe manner.

Available for most cam and groove styles, PT Pressure Safe automatically prevents rapid separation of the fittings in a fluid or dry material delivery system. Based on the NASA hardware modifications, PT Pressure Safe will not allow a user to close the arms on the coupler until the two pieces are locked and rotated 45 degrees. If released under pressure, the modification ensures the coupling halves will not disconnect. Once the pressure in the delivery system is sufficiently low, the adaptor can be rotated and be safely disengaged. According to Eckhardt, the simplicity of the design is what makes the fittings so unique and versatile.

“In the event that the hose connections are opened under pressure, the PT Pressure Safe will prevent the fittings from separating completely. The feature allows the operator to safely open the fittings under pressure by preventing rapid separation of the coupler and adapter, protecting the operator and surrounding equipment from personal injury and damage,” says Eckhardt. “Anyone concerned with safety with cam and groove fittings would want to use PT Pressure Safe.”

Potential customers for the PT Pressure Safe are the petroleum and chemical industries, and any industry that transports liquid under pressure. The company currently offers 2- and 3-inch sizes, but can develop and manufacture most sizes.

For such a small piece of hardware, the fittings have the potential to make a big difference. As Eckhardt says, “NASA allowed us to have the technology and offer a brand new product line to our customers, which could make industry much safer.”

The PT Pressure Safe cam and groove system from PT Coupling Company utilizes technology transferred from NASA. The system prevents personal injury and property damage by ensuring the coupling halves on a delivery system do not disconnect while under pressure.

In the Space Station Processing Facility at Kennedy Space Center, an overhead crane lowers the International Space Station’s Tranquility module. It is here where NASA engineers made a particular modification to some fittings that is now incorporated into commercial fittings for the petroleum and chemical industries.