Eating on Demand

There is nothing like a warm, home-cooked meal. It can be a particularly welcome delight after a hard day's work aboard a space station, hundreds of miles above Earth.

Fast-cooking technology, prompted by the requirements of space station designers at the Johnson Space Center, has led to a new generation of commercial and residential ovens. Enersyst Development Center of Dallas, Texas was engaged by NASA, as part of a space station team, to create specialized cooking equipment. The mandate was straightforward: Offer flight crews food variety, produced in a quantity and with the speed that would enable shared meals. Equally important was building a compact oven that demanded little of an astronaut's valuable time. These demands could not undermine the quality of the eating experience, nor the nutritional needs, mood and tone of space station crew members.

Enersyst tackled a number of challenges related to cooking and cooling in space. Easy preparation and operation of the device were essential; the oven had to be low-weight, yet was required to operate on little electrical energy; and the unit needed to be simple to clean and repair. Another key consideration was the control of effluents from the apparatus. Odors, water vapor, grease, and smoke produced by an oven might harm critical space station equipment. Therefore, filtration and collection control of oven fumes became more important than on Earth.

The solution from Enersyst was air impingement technology. The concept uses jets of hot air at the top and bottom of the oven that are focused on the food, rather than just heating the oven cavity as in a traditional thermal oven. By heating the food directly, foods cook faster and more consistently, retaining their flavors and textures. Embodied in Enersyst's space station prototype oven were state-of-the-art controls to provide pre-stored heating programs, all available at the push of a button. A full manual backup system was also provided as a redundancy.

The challenges of preparing space flight cuisine were found to have a common link to an earthly reality: On-the-run consumers do not have time to cook. In many cases, people are unsure how to best prepare certain foods. Eating on demand and quality food, but in a flash, have become a part of daily life.

Enersyst has blended the air impingement idea with microwave assist, thus enhancing cooking speed while retaining the quality, taste, and appearance of the food. The microwaves heat and move water from the interior of the food to the exterior, helping in the process of cooking the food uniformly. With Enersyst technology, food can be cooked up to two to four times faster than in conventional ovens. For example, how about cooking a 12-pound turkey in just 75 minutes? Pizza, burgers, and other similar items can also be cooked in short order.

Enersyst's work on a space station oven has successfully migrated to the food service marketplace. The firm has patented the technology and has licensed it to restaurant equipment manufacturers. Vending units incorporating Enersyst innovations are being marketed in the United States, Japan, and the Pacific Rim by KRh Thermal Systems, an Enersyst licensee.

Equipment for food processing plants and restaurants, as well as vending and home applications are now part of the company's overall work in the world of food preparation. Restaurant chains like Domino's and Pizza Hut have incorporated Enersyst's air impingement technology through products offered by Lincoln Foodservice Products, Inc. and Middleby Marshall. In 1997, Enersyst began working with Thermador to establish a new line of residential ovens, bringing fast-cooking technology to the home consumer. The company's foray into the home market is one that promises to be a fast-growing venture.

Explains Sarah Palisi, Enersyst's Chief Executive Officer: "In a world where time and convenience are greatly limited, it's exciting to offer consumers the ability to enjoy the quality, flavor, and speed derived from restaurant cooking, at home."

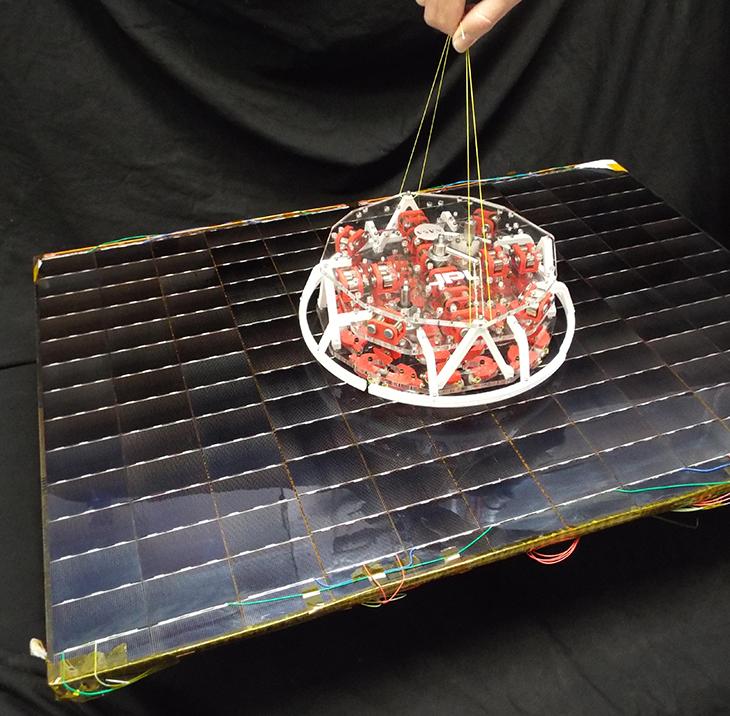

A prototype oven for use aboard the space station has led to appliances that cook food faster, yet retain food quality.

Vending units that provide hot foods incorporate technology designed for use aboard the space station.