Big Savings from Smart Motors

Originally published in 1984

Body

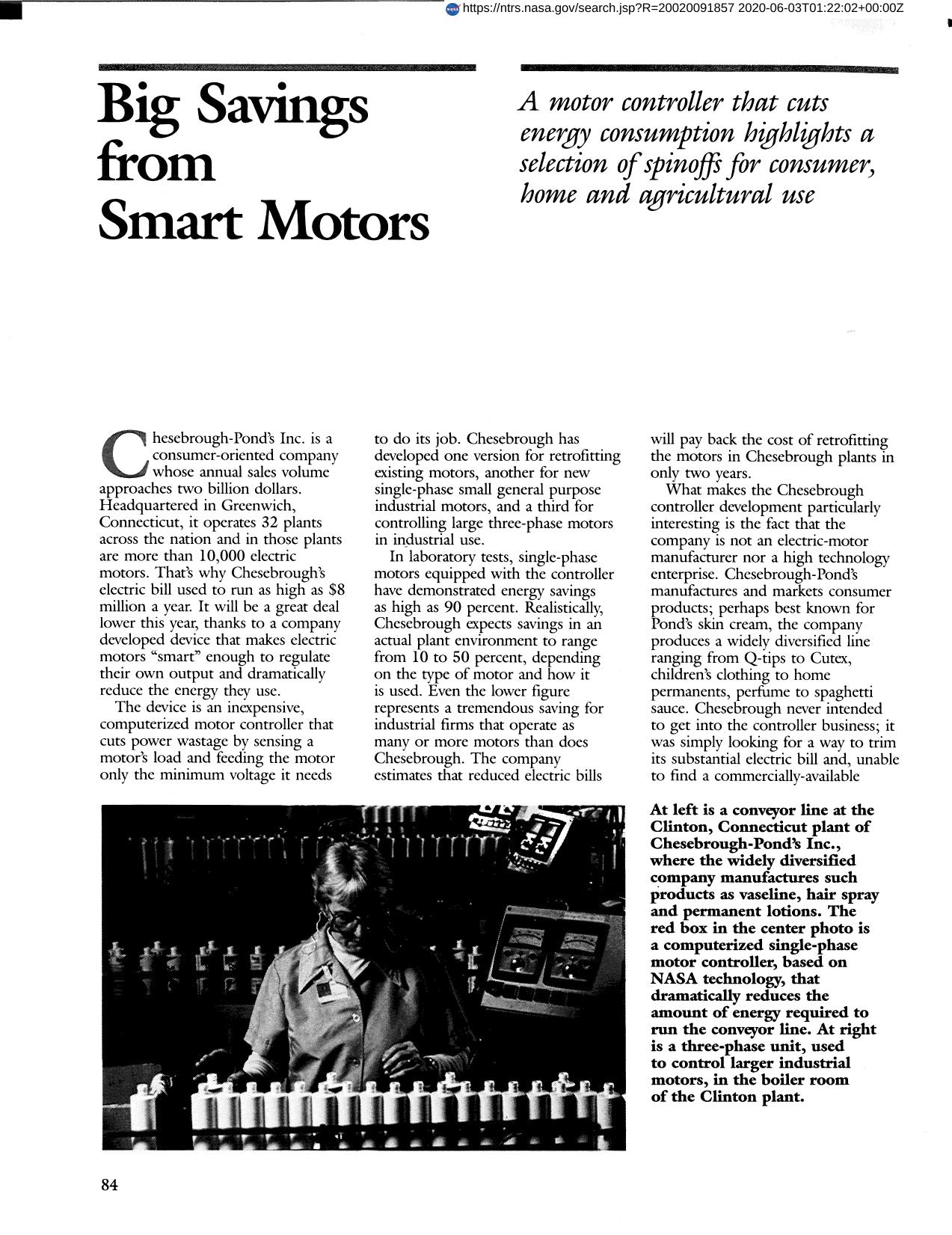

Chesebrough-Pond's operates 32 plants across the nation and in those plants are more than 10,000 electric motors. In an effort to cut down on waste of electrical power used by these motors, Chesebrough organized a Corporate Advanced Technology Group to devise ways of improving productivity and cut manufacturing costs. Chesebrough used NASA's Marshall Space Flight Center's Power Factor Controller technology as a departure point for development of their own computerized motor controller that enables motors to operate at maximum efficiency regardless of the motor's applications or operating condition.

Full article: http://hdl.handle.net/hdl:2060/20020091857

Abstract

Chesebrough-Pond's operates 32 plants across the nation and in those plants are more than 10,000 electric motors. In an effort to cut down on waste of electrical power used by these motors, Chesebrough organized a Corporate Advanced Technology Group to devise ways of improving productivity and cut manufacturing costs. Chesebrough used NASA's Marshall Space Flight Center's Power Factor Controller technology as a departure point for development of their own computerized motor controller that enables motors to operate at maximum efficiency regardless of the motor's applications or operating condition.

Big Savings from Smart Motors

Big Savings from Smart Motors