CO2 Recovery System Saves Brewers Money, Puts Bubbles into Beer

NASA Technology

Building on work he and his companies did with Johnson Space Center’s In Situ Resource Utilization (ISRU) team, Robert Zubrin has developed and commercialized technologies that could prove revolutionary in their Earth applications, such as a system that could extract millions of barrels of oil from defunct oil wells around the world and another that can harness all the natural gas currently burned off as waste at many oil drilling rigs (Spinoff 2015).

But when he’s not working to change this world or colonize others, the president of Pioneer Astronautics, Pioneer Energy, and the Mars Society enjoys a good microbrew. Now, he’s applied some of that same technology to cut costs for craft breweries that produce anywhere between 3,000 and 300,000 barrels per year.

Beginning in the mid-1990s, as a NASA contractor and then as founder of Pioneer Aeronautics, Zubrin worked with Johnson’s ISRU team to develop technology that could break down elements that are abundant on Mars and turn them into essential resources for exploration missions. Early work devised means to capture the carbon dioxide (CO2) that comprises more than 95 percent of the thin Martian atmosphere and turn it into oxygen and fuel. He built systems that could, for example, collect and separate CO2 from other gases, raise its pressure by two orders of magnitude, combine it with hydrogen to make methane and water, break the water down into oxygen and hydrogen, and remove water vapor from the resulting oxygen before it was stored.

Some of this technology, such as systems that manipulate temperature and pressure to liquefy and store gases or to strip water from a gas, as well as the technology that allows such systems to run autonomously, has found its way into Lakewood, Colorado-based Pioneer Energy’s latest creation, the CO2 Craft Brewery Recovery System.

Technology Transfer

“When you ferment beer, the process that produces alcohol also produces carbon dioxide,” Zubrin explains, noting that CO2 is also necessary later, to carbonate the beverage.

Major breweries typically have systems that capture the carbon dioxide produced during fermentation for use in carbonation and other functions, such as purging process tanks. These are high-capacity, multimillion-dollar systems, however, and don’t make sense for a small craft brewery. “They don’t have the capacity to liquefy the carbon dioxide that comes off their fermenters to put it into the beer,” Zubrin says. Instead, microbreweries are left to release the gas from fermentation and buy carbon dioxide from an outside vendor.

Pioneer’s CO2 recovery system fills that gap. “We made a system that would produce about five tons of carbon dioxide per month,” Zubrin says, adding that this is enough for a brewery that generates up to about 60,000 barrels per year, and units can essentially be stacked to increase that capacity. “Two of my key engineers, Andy Young and Matt Lewis, saw the need, and together with the rest of the team, created a flexible system that works like a charm.”

“We’ve taken our general technology acumen, which we developed under NASA, and applied it here,” Zubrin says. “If you want to get CO2 from the Martian atmosphere, you want to compress it, and you want to liquefy it.” With some modifications, the same technology can put the bubbles into beer.

On Mars, carbon dioxide would more likely be frozen, at least initially, rather than liquefied, says Gerald Sanders, chief ISRU engineer at Johnson. But the products made from it would be stored as liquids. “The types of technologies Bob is talking about to liquefy carbon dioxide are similar to technologies we would use to liquefy and store any oxygen or methane we produced on Mars,” he says. “It’s a similar process. It requires things like mechanical compressors and cryocoolers.”

Liquid CO2 could also come in handy on the Red Planet, as some NASA researchers are looking into the possibility of using it for washing clothes during a Mars mission, Sanders says. “What Bob has done could fall into that realm if we decide to go that route.”

Another commonality is the use of devices like desiccant beds, which Sanders says would be used on Mars to remove any remaining water molecules from final products before storing them. “Before you liquefy oxygen or methane, you have to strip water out of it.”

“The fermenters in breweries have water in them, and you’ve got to keep it out of the carbon dioxide, or it will freeze in the lines and block them,” says Zubrin, noting that this is where desiccant beds enter into Pioneer’s CO2 recovery system.

“None of this is really new physics, although we do use our own blend of refrigerants, which is new,” he continues.

Any system for mixing and matching molecules on Mars would also have to be fully automated using techniques Zubrin worked out during his years of ISRU work. “Typically, for the missions to Mars we’ve been considering, we would send the return vehicle 26 months before the crew even leaves,” Sanders says, noting that systems on the vehicle would produce resources for both the mission and the journeybefore the astronauts arrive. And they couldn’t even be controlled remotely in real time, as there is a communication delay of around 4 to 24 minutes each way, depending how far apart Mars and Earth are at the time.

In the case of a brewery CO2 recovery system, while the device may save a couple thousand dollars a month, it wouldn’t be economical to hire an employee to run it, Zubrin says. “On a smaller scale, this thing’s got to be totally automated, too. The robotic control you would need for a system on Mars is key to this.”

“Even if it’s not 100 percent something we would use on Mars directly, there’s a lot of synergy between what he’s done in the past and what he’s doing here,” Sanders says.

Benefits

Carbon dioxide typically runs about $200 to $300 a ton, although costs can be much higher depending on the distance from a source, Zubrin says, noting that, while the price is currently around $300 in Denver, breweries in Durango 300 miles away are paying $600 a ton. A typical brewery producing 60,000 barrels a year and paying $300 a ton for CO2 would save around $15,000 a year by using Pioneer’s recovery system, he says. The units are priced to pay for themselves within two years or so.

Quality is another advantage the system offers. The carbon dioxide brewers buy is typically a byproduct from ammonia and urea plants and may not be entirely pure, Zubrin says. “Here, you’re getting it pure from the fermenter, so it’s high-quality CO2, without even the slightest trace of industrial contaminants. We have tested it, and it is free from air contamination as well.”

And, of course, the technology allows reuse of a greenhouse gas that would otherwise be released into the atmosphere.

By June 2015, the company had taken at least a dozen orders, and the system went into production late last year. Pioneer also has a unit that it brings around the country for demonstrations. Zubrin says the technology has already received a lot of interest. He notes that microbreweries have proliferated over the last decade, a trend that continues today. “Within the United States, there are several thousand breweries that would be targets for this, and probably 20,000 worldwide.”

He credits his NASA work with the money and greenhouse gas emissions he plans to save breweries around the world.

“The intellectual capital being developed in NASA’s research and development programs is playing out across the economy, and this is just a small example,” Zubrin says. “The intellectual capital is the big spinoff.”

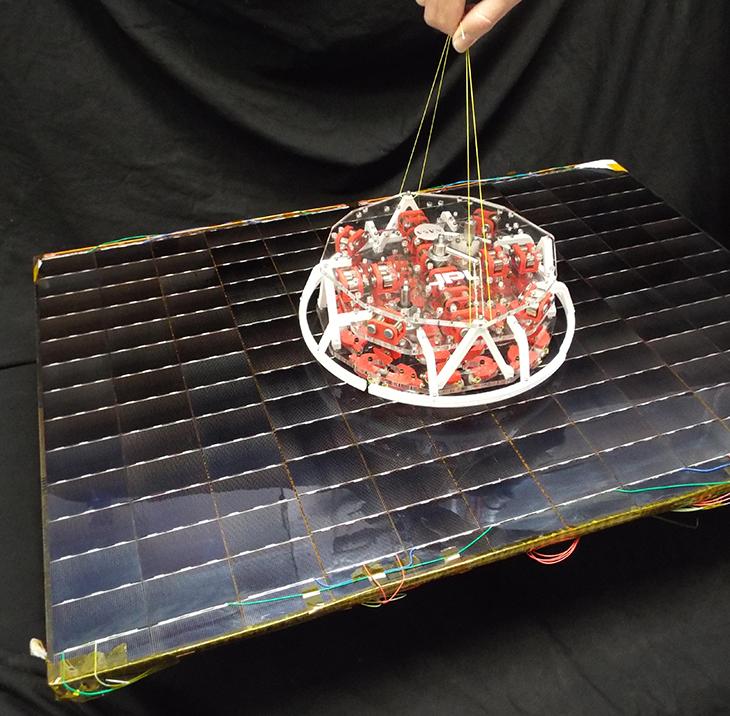

Pioneer Energy’s CO2 Craft Brewery Recovery System can recapture about five tons of carbon dioxide per month, enough for a brewery that generates up to about 60,000 barrels per year, and units can be stacked to increase that capacity.

While major breweries have long had systems to capture the carbon dioxide generated during fermentation for reuse in carbonation and other functions, the technology has not been available on a smaller scale, forcing the more experimental microbreweries to buy carbon dioxide. This is the niche Pioneer Energy aims to fill.. Image courtesy of Quinn Dombrowski, CC BY-SA 4.0