Robotics Algorithms Provide Nutritional Guidelines

Originating Technology/NASA Contribution

On July 5, 1997, a small robot emerged from its lander like an insect from an egg, crawling out onto the rocky surface of Mars. About the size of a child’s wagon, NASA’s Sojourner robot was the first successful rover mission to the Red Planet. For 83 sols (Martian days, typically about 40 minutes longer than Earth days), Sojourner—largely remote controlled by NASA operators on Earth—transmitted photos and data unlike any previously collected.

Sojourner was perhaps the crowning achievement of the NASA Space Telerobotics Program, an Agency initiative designed to push the limits of robotics in space. Telerobotics—devices that merge the autonomy of robotics with the direct human control of teleoperators—was already a part of NASA’s efforts; probes like the Viking landers that preceded Sojourner on Mars, for example, were telerobotic applications. The Space Telerobotics Program, a collaboration between Ames Research Center, Johnson Space Center, Jet Propulsion Laboratory (JPL), and multiple universities, focused on developing remote-controlled robotics for three main purposes: on-orbit assembly and servicing, science payload tending, and planetary surface robotics. The overarching goal was to create robots that could be guided to build structures in space, monitor scientific experiments, and, like Sojourner, scout distant planets in advance of human explorers.

While telerobotics remains a significant aspect of NASA’s efforts—as evidenced by the currently operating Spirit and Opportunity Mars rovers, the Hubble Space Telescope, and many others—the Space Telerobotics Program was dissolved and redistributed within the Agency the same year as Sojourner’s success. The program produced a host of remarkable technologies and surprising inspirations, including one that is changing the way people eat.

Partnership

The Space Systems Laboratory (SSL), focusing on space robotics, artificial intelligence, and space simulation, was originally founded at Boston’s Massachusetts Institute of Technology in 1976. The lab conducted experiments on large-scale space structure assemblies and telerobotics using Marshall Space Flight Center’s Neutral Buoyancy Simulator, a water tank used to mimic conditions in space (NASA’s neutral buoyancy facility is now located at Johnson). Along with Marshall, SSL spearheaded the 1985 Experimental Assembly of Structures in Extravehicular Activities (EASE) experiment, which studied astronaut proficiency in assembling structures during spacewalks, as well as possible building and maintenance techniques. The success of the EASE experiment boosted interest in telerobotic applications for construction in space. In 1990, SSL moved to the University of Maryland, College Park, where it built a Neutral Buoyancy Research Facility—a 50-foot-diameter, 25-foot-deep water tank—that became the site of one of the Space Telerobotics Program’s major projects: the Ranger Telerobotic Flight Experiment.

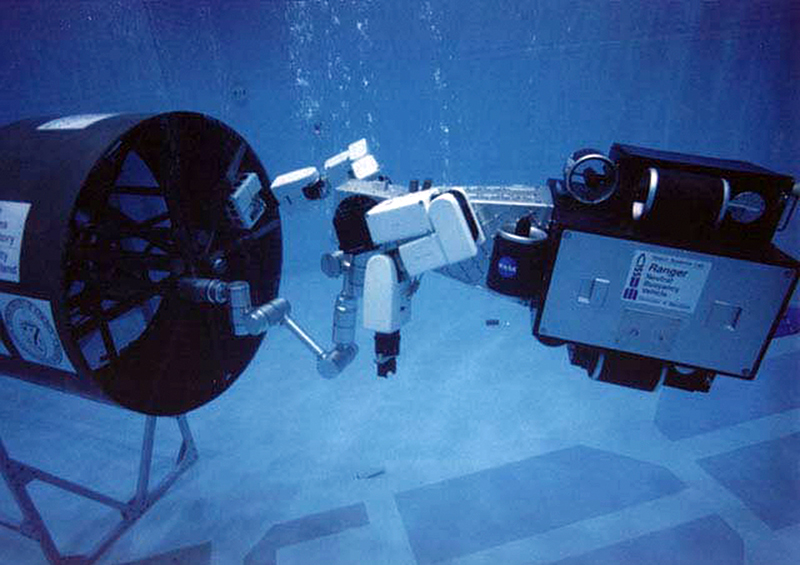

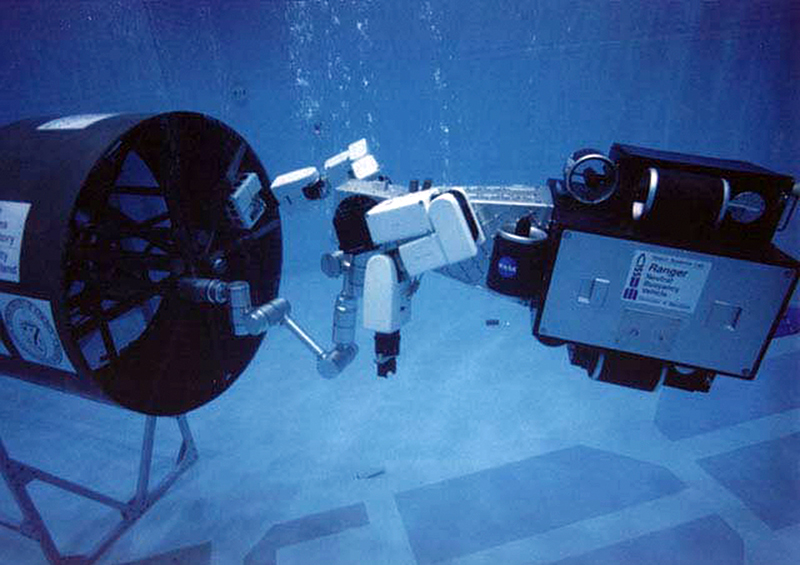

Funded through what was then the Telerobotics Intercenter Working Group, part of the NASA Headquarters Office of Space Sciences (now the Science Mission Directorate), Ranger was SSL’s effort to produce a free-flying robot capable of assisting astronauts with tasks such as structural repairs, assembly, and on-orbit refueling. The lab developed a test robot for underwater operation—the Ranger Neutral Buoyancy Vehicle (NBV).

“Ranger was designed to easily transition from water to space,” says Joe Graves, who as a master’s and later PhD candidate served as a lead engineer for Ranger NBV. “The robot was not necessarily designed to replace astronauts. We were trying to determine how a robot could be helpful to human operations.”

Though Ranger NBV is no longer part of an official NASA program, Graves has moved on to a new project, one that leverages the telerobotics experience he developed from the Ranger program to help revolutionize an entirely different field: nutrition.

Product Outcome

In 2003, Graves founded Vitabot, an online nutrition company headquartered in Beltsville, Maryland, that uses some of the same robotics and computer science concepts that he developed for the Ranger NBV—in this case, to offer a product that helps customers determine and maintain their ideal diet. Graves hit on the idea when he noticed the disconnect between the vast amounts of nutritional data available to the public and how that data is actually used. He noted that the U.S. Department of Agriculture (USDA) offers complete breakdowns of what composes various foods—far beyond what is offered on food labels—and that the Institute of Medicine, a nonprofit division of the National Academies of Science, publishes reports that gather research from around the world to determine nutritional needs.

“On one end, you have the USDA putting out exactly what’s in food, and on the other you have the Institute of Medicine putting out the nutrition you should have,” says Graves. The problem he saw was that the public had no convenient way to make use of this information. “If I could think of one field in which the data and the application of the data are so incredibly removed from each other, it would be nutrition,” he says.

Graves realized this challenge was similar to one he faced with the Ranger NBV. The robot has more than 20 computers controlling different joints, navigation systems, and thrusters, all requiring complex data to manipulate. “We had this enormously intricate system with all these equations to position the arms and all these controllers to manipulate the arm positions, but as the human operator, I don’t want to think about all that,” he says. “I just want to reach out and grab something.” For the Ranger NBV, the solution was to create intelligent software to mediate between the operator and the robotics data. Graves saw the same idea could work for nutrition.

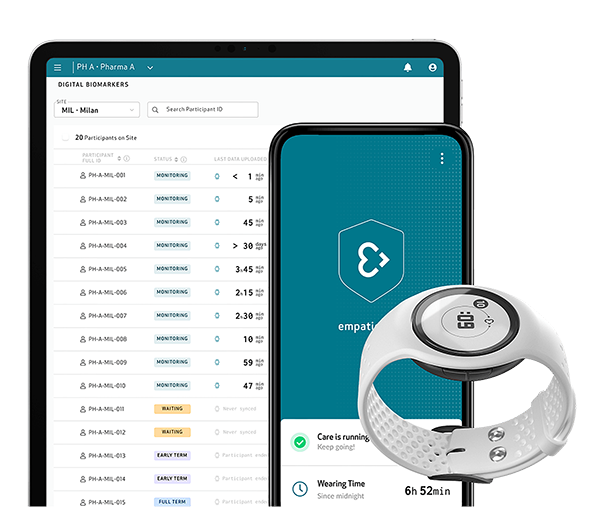

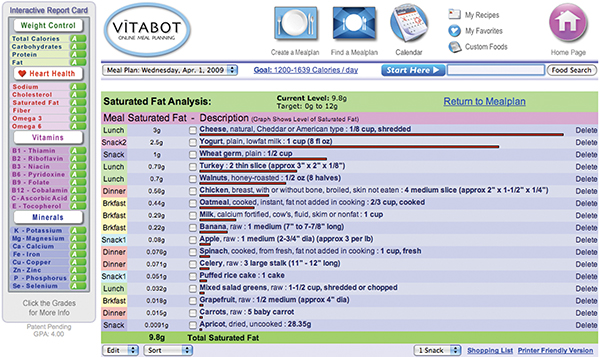

“Vitabot uses the exact same style of algorithms that we developed between the robot and the operator,” says Graves. The result is an easy-to-use online program that allows users to set health goals like desired weight and then plan balanced meals using a food database featuring tens of thousands of choices. Available through corporate wellness programs and health clubs, Vitabot centers around an interactive report card that grades how food choices measure up to users’ nutritional needs in a wide range of categories including calories, fat, electrolytes, minerals, and vitamins. Users can build complete menus of favorite foods that also match their nutritional needs, allowing them to make real, individually tailored use of the previously overwhelming quantities of available nutritional data. Vitabot’s algorithms guide the users’ choices to help them get complete nutritional balance. The resulting balanced menus are then shared through Vitabot’s Ultimate Mealplan Project, where other users can then modify and improve these menus, guided by Vitabot’s suggestions. “This creates a massive group experiment where individuals, guided by their own personal tastes and the requirements of the Institute of Medicine, are mapping out an enormous space of carefully balanced meal plans,” says Graves.

Though the focus of Vitabot is on balanced nutrition and not weight loss, the latter is often a result of the former, Graves says. The company now counts the likes of HBO and Warner Bros. among its nearly 1,000 company clients and has experienced over 1,500-percent growth in the health club industry in the last year, with major chains like Gold’s Gym offering Vitabot to its members. Recently, the U.S. Air Force has started using Vitabot at several of its bases.

Graves credits Vitabot’s unusual origins for much of its success; most nutritional planning systems do not come out of a space program, he says.

“It’s a different paradigm that has created a different solution.”

Vitabot® is a registered trademark of the Vitabot Network.

The Ultimate Mealplan Project™ is a trademark of the Vitabot Network.

HBO® is a registered trademark ofBox Office Inc.

Warner Bros.® is a registered trademark of Time Warner Inc.

Gold’s Gym® is a registered trademark of Gold’s Gym International Inc.

Vitabot uses robotics algorithms to help users take advantage of vast amounts of detailed nutritional data and develop balanced meal plans.

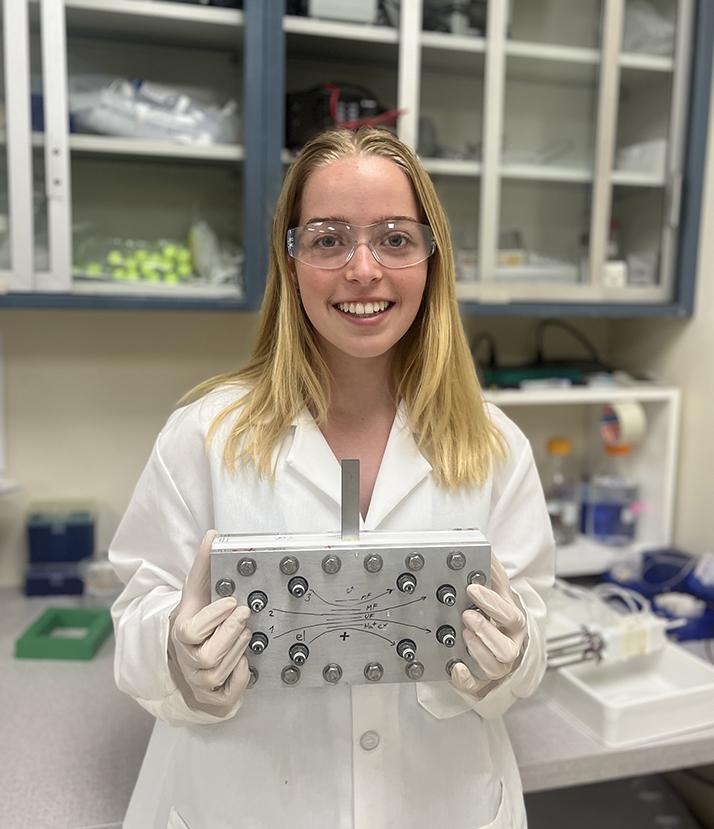

Developing NASA’s Ranger Neutral Buoyancy Vehicle provided Joe Graves with the robotics experience he used to create the online nutritional program Vitabot.