Experiments With Small Animals Rarely Go This Well…

Originating Technology/NASA Contribution

In the mid-1950s, a young U.S. Air Force engineer named Clark Beck began work with what is now one of NASA’s most prolific spinoffs, the radiant barrier technology. Beck’s work involved creating materials that could withstand the immense heat created by passage through the Earth’s atmosphere. He was working on structures and resources that could withstand the fluctuations in temperature created by a skip reentry, where a craft would “skip” along the surface of the atmosphere, gradually making inroads sufficient for reentry, a process that took the craft from extreme heat to frigid cold every few seconds. The material also needed to withstand millions of pounds of pressure per inch of bending without twisting, the simulated force of reentry. Without reflective material, the craft would get what Beck refers to as “red hot wings,” and without the required flexibility, the craft would break apart.

One result of Beck’s work was the discovery of the useful properties of radiant barrier material. The Space Agency used Beck’s design work for the materials that went into building the space capsules, heat resistant instrument panels, and, in conjunction with the Air Force, an early spacecraft prototype, the DynaSoar, that looks remarkably similar to the present-day Space Shuttle.

NASA used the thin, shiny, silver material to protect the first space explorers from the harsh environment of space, which could range from -460 °F to 541 °F. If the engineers had used conventional insulation for the space suits, the fabric would have been 7-feet thick, a little awkward for even the most nimble of astronauts to maneuver. Radiant barrier technology was clearly the solution. It reflected the astronaut’s body heat back into the suit to keep him warm, while at the same time reflecting radiant energy from the Sun outward to keep him cool.

The radiant barrier material reflected more than 95 percent of the radiant energy away from the wearer, while tiny holes in the fabric allowed moisture to escape and longer heat waves to get through. This amazing fabric had an added benefit that made it ideal for its space-bound application: It weighed only 17 pounds per 1,000 square feet.

NASA has used this material ever since the Gemini and Apollo missions, on virtually all of its spacecraft, and even on unmanned missions as thermal protection for instruments..

Partnership

NASA’s radiant barrier technology has been public domain for the past 3 decades. It is used in “space blankets” and countless other applications, including energy-savinginsulation, awnings and canopies, agricultural insulation, automotive insulation, and protective apparel, the likes of which is used by firemen. These are only a few of the many applications found for this material.

Scratch and Newton, Ltd., a company with worldwide Internet sales, employs this technology to improve the lives of pet rabbits and guinea pigs. Experiments involving small, cute, furry animals almost always end badly for the critters. In this instance, though, science and cute animals can coexist.

Product Outcome

Scratch and Newton has a clever premise: Scratch, a fumbling rabbit, has a slew of problems, and Newton, a genius guinea pig, tinkers at his workbench to solve them. The “solutions” are the company’s products. They include hutch covers, run covers, and bottle wrappings. The ideas and products actually come from company founders Chrissie Slater and Lydia Ross, two Britons who had been experimenting with bubble wrap, thick unplasticised polyvinyl chloride, and other materials that were hard to work with and had significant problems, like breathability and condensation. After extensive experimenting, they decided that, as Slater says, “The radiant barrier is just ace!”

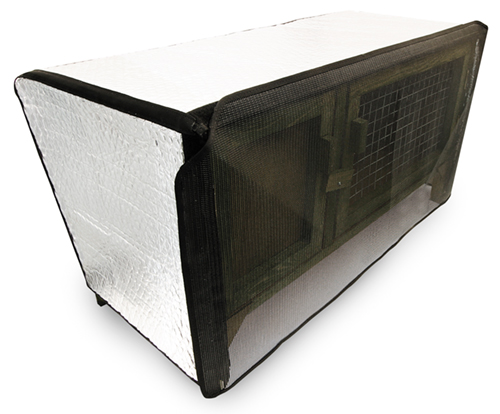

The Hutch Snuggle protects the outdoor pet rabbit or guinea pig from the elements. Made of the radiant barrier material, it helps reduce summer heat gain and winter heat loss, making the animal’s environment more comfortable. The rabbit or guinea pig gets a comfortable shelter from the harsh elements in the winter and a cool patio in the summer. The Hutch Snuggle even features a clear window for the pet to look out and the keeper to look in. Used in conjunction with the Hutch Hugger, a hutch cover made of weather-resistant fabric, the pet is guaranteed to be safe from wind and rain. All of these items come in different sizes, so they should fit just about any hutch. Custom-made hutch covers, however, are also available.

These little pets cannot spend all of their time locked in hutches, though. They need to stretch and exercise. For this purpose, Scratch and Newton also makes the Run Hugger, a radiant barrier cover for the animal’s play pen. This way, even when the weather gets especially rough, the animal can still have some much-needed daily play time.

The Bottle Snug, another product developed by Scratch and Newton for the small critters, is designed to keep a pet’s water supply fresh and drinkable. The radiant barrier bottle cover prevents water from freezing during winter months and keeps water cool and fresh during the hotter seasons. This also cuts down on the green algae that can sometimes grow in water bottles in warmer weather.

Scratch and Newton has sold its products around the world, though it plans to target Canada,to many chilly bunnies, and New Zealand, land of the overheated pet guinea pigs. It plans to proceed with its line of thermal critter-care products and look to NASA technology to find other innovations that may be of use.

Clark Beck, the engineer who pioneered the radiant barrier technology, is now retired, though still active in his local Dayton, Ohio, engineers club, and not surprised by the widespread use of the radiant barrier technology. He has seen it used in myriad ways. “Its uses are only limited to one’s imagination,” he says. “It can be used wherever you find heat or cold.”

Hutch Snuggle™, Hugger™, Run Hugger™, and Bottle Snug™ are trademarks of Scratch and Newton, Ltd.

The Hutch Snuggle keeps the pet’s hutch cool in the summer and warm in the winter.

Frankie and Munroe are fur-ever pleased to have their fresh water protected by the Bottle Snug.